How To Choose Right Fiber Laser Cutter?

- Home

- Fiber Laser Machine TECH

- How To Choose Right Fiber Laser Cutter?

How choose Right fiber laser cutter?Guild to beginner

lots Of customer don’t know how choose right fiber laser cutter from all types type of laser machines on the market.

following tips for your reference:

1.What thickness of your metal?what material mainly?

Generally speaking,there are three type of different class.500W-3000W fiber laser cutting machine

3000W-6000W laser cutting machine 10000W,120000W

First stype is less than 3000W fiber laser source..it mainly cuts carbon steel at 12mm or stainless steel 5mm

if you cuts aluminum or copper than need choose higher power laser source because of copper,aluminum is reflected material not easy to absorb laser lights.

2.What working area of laser cutter?supporting customize

1300mm*900mm or 1500mm*3000mm or 2000mm*6000mm is more popular.

we could customize any size

3.cutting table between single table or exchange up and down cutting table?

feeding metal material by human labor at same time improve working speed.

4.What configuation of fiber laser cutter?

laser source,laser head,controlling system,water chiller,guild rails and servo motor for X,Y,Z .

machine’s configuation is most important factor for laser cutting machine works.

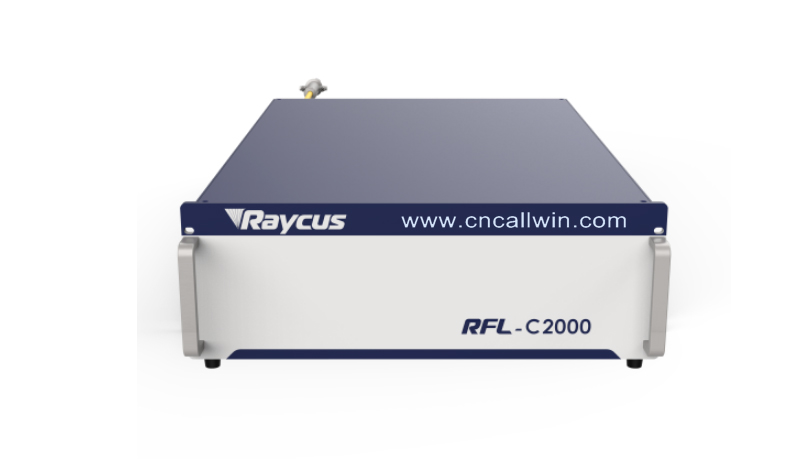

laser source is as heart of machine.it is most part in fiber laser machine.

As you can see,when choosing a fiber laser cutter with a specific power.it is worth considering not only the thickness of the metal sheet to be cut..but also the type of material.

when cutting black steel.its thickness of cutting material even with a 2000W laser source can reach upto 16mm

in case of the other material,such as brass,the capabilities of the laser will be weak.

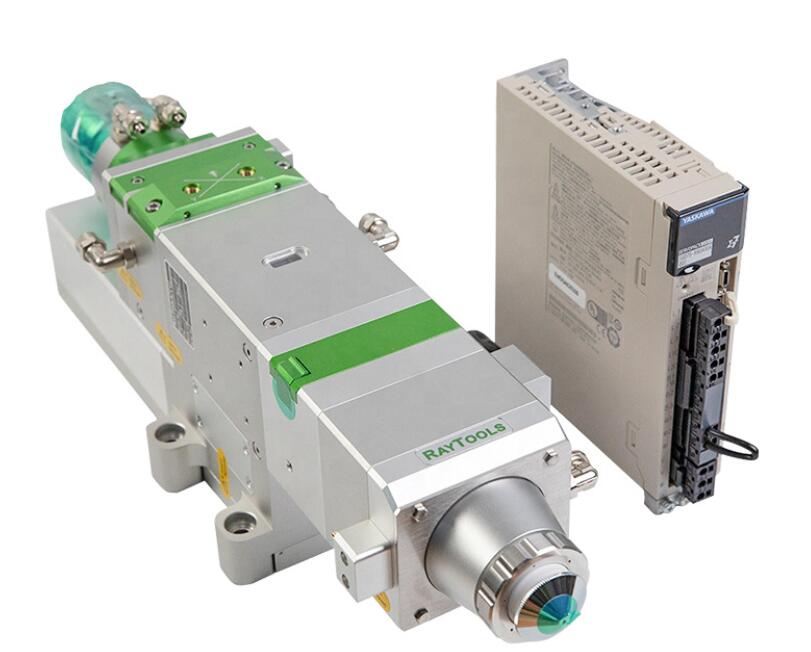

laser head is consists of five basic units, such as collimated water-cooled

module, collimation centering module, focus drive module, protective lens module, nozzle module.

we always use swiss Raytools with automatic focus.

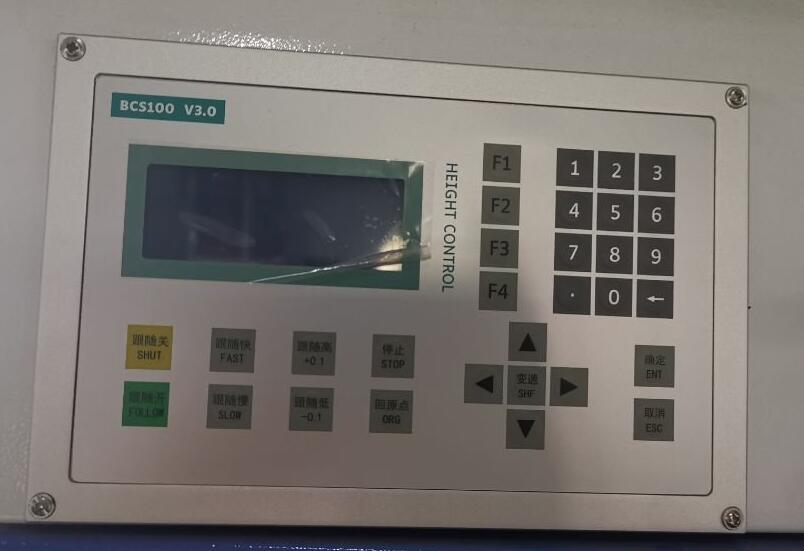

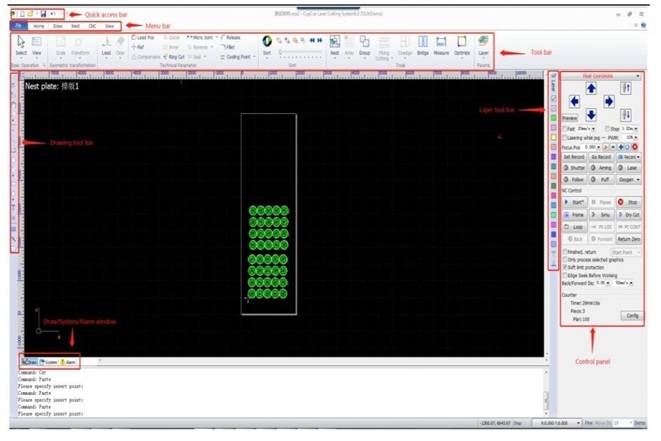

laser cutting control system is as brain of machine.it guild laser cutting machine where to go?

lots of suppliers use cheap price trick to cheat on customers who know nothing about fiber laser cutter..We suggest to use cypcut laser cutting control system because it has very sensitive Z axis callibration screen.lots of cheap control system make laser head hit metal sheet or sudden failure during works.

water chiller is as suppying water to fiber laser cutting machine is also very important.our water chiller has water temperature alarm..it will alarm voice once your laser head is higher or lower temperature.which helps to protect our laser machine.

Servo motor for X,Y,Z and laser head.It decides what speed does machine goes?what about noisy? and machine moves at precise or deviation? we use Japanese yaskawa motor driver.it could resist very strong signal interference.

in all in,we need check our money in the pocket to choos right fiber laser cutting machine.

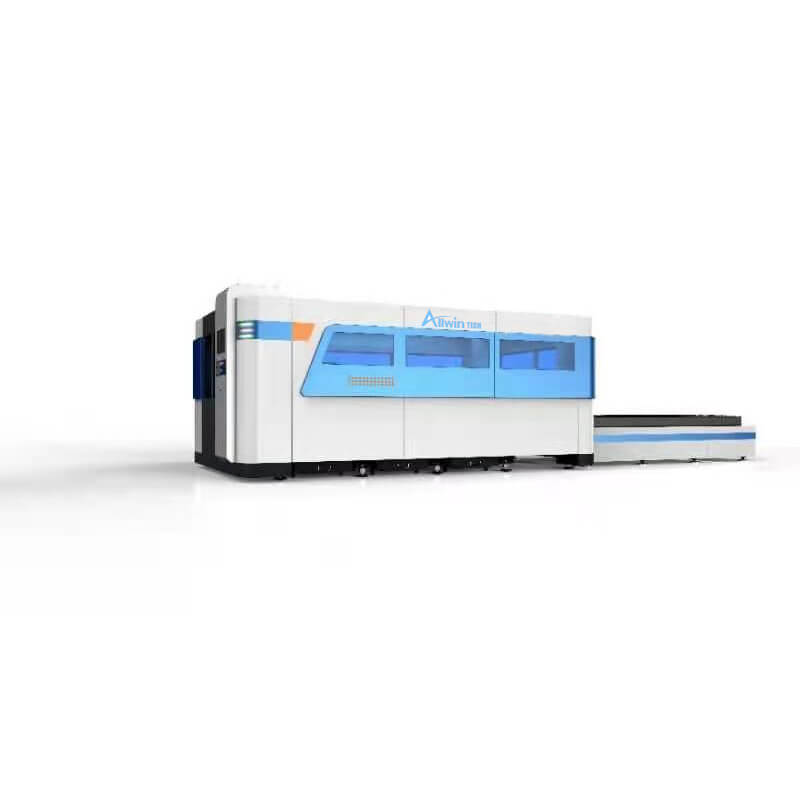

Industrial fiber laser cutter for metal pipe and metal sheet

good price fiber laser cutter for metal sheet 3015

6000W fiber laser cutter with exchange cutting table with full cover high power laser source

Mini portable lower power fiber laser cutting machine 9013

for silver or gold

Summary how choose from many type of fiber laser cutter?

after talking too much above.

It would be best if optimally matched the choice of laser source power to your needs.

First,think about what your workshop needs most;

for example,do you intend to cut as an service?in which case the thickness of materials cut will probably be more diverse?)

or do you ned a fiber laser cutting machine only for your own shop?

which type of metal materials are most often processed?

the thicker parts we want to cut,the bigger laser source we need.

of course,You should take into consideration that A higher power of the machine is also come with its higher price.

most available hot sales on the marekt is 2KW-6KW.

We also have fiber laser cutting machine with higher power—the higher power laser machine are often unaffordable.

We hope this article could help you to give you clue for how choose right fiber laser cutting machine