CNC Router Table Manufacturer

3 AXIS CNC,4 Axis and 5 Axis CNC Router With Additional Attachment Auotomatic Tool Changer/Rotary Axis.Very competitive Price with faster Service Support.

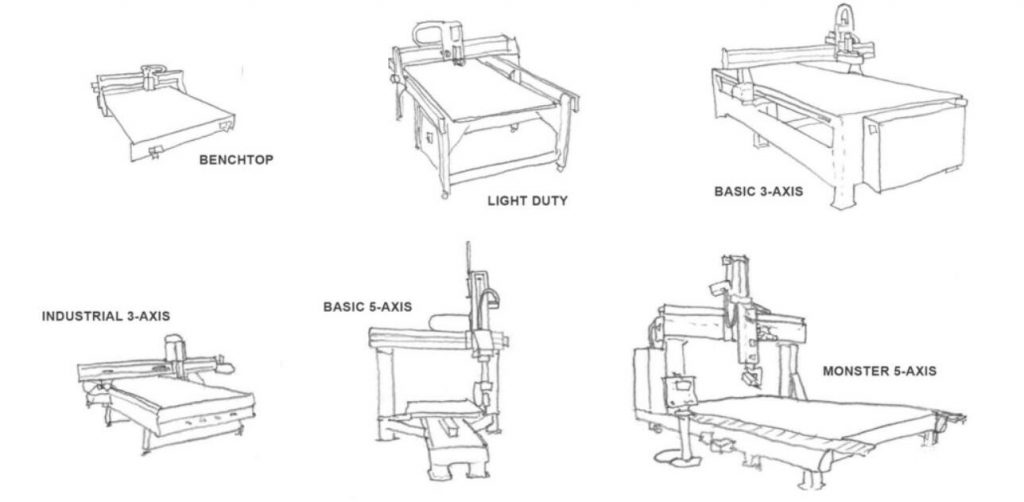

What type of CNC router do you need?

This pictures shows All catalogues cnc router machine that are hot sales on market.

1.Desktop cnc router 2.Light duty style 3.Basic 3-Axis 4.Industries 3 Axis CNC Router. 5.basic 5 axis cnc router

6.Heavy duty 5 axis cnc router machine.

aditional attachment:Rotary axis to process with cyclinder bar(like table legs)

Automatic tool changer(linear type or carousel style)–to replace of tool change by hand.

what is CNC router?Why use CNC router?

What is CNC router?

CNC (Numerical Control Machine Tool) is short from Computer numerical control, which is an automated machine tool equipped with a program control system. The control system can logically process the programs with control codes or other symbolic instructions, and decode them, so as to make the machine tool move and process parts

Why use CNC router?What does CNC router do?

1)CNC router could cut material also could engrave on materials,that is another name is CNC Engraving machine.

2)more and more CNC industries or workshops are chasing on fast working speed because of high labor cost

2)CNC router could make any things according to your design things in your computer.it forces designers have very differently thoughts about design on different works plus

3)CNC router could work with different materials that is why You could see CNC router everywhere at different industries.

if you are working on belowed industries below than you better buy one CNC router.

1. Advertising and gift production,carve or engrave on all kinds of two-color plate signs, plexiglass, three-dimensional billboards, two-color figure statues,

Embossed medals, organic board embossed, three-dimensional door header, etc.

2. Model making industry, making sand table models, house models, or shoes models So on.

3. Mold manufacturing industry, engraving button embossing molds, printing hot stamping molds, injection molds, stamping molds, shoe molds, etc.

4. Woodware industry, used for relief pattern design and production.

5. Circuit production, drilling, slot milling, etc. in the development of new printed circuit boards.

6. Seal industry, seal engraving of various fonts and materials.

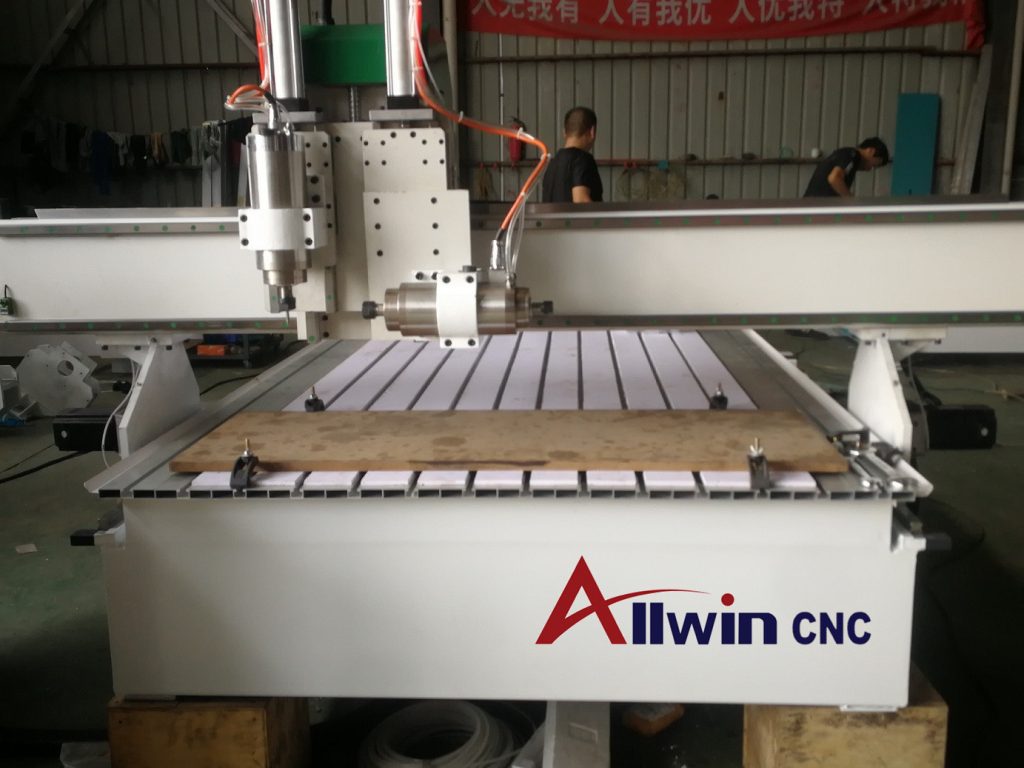

custom woodworking desktop cnc router two spindle to work with drilling door.it is best choice for processing doors and locks grooves or cabinet.

Rocking chair or home decoration works are made by 3 AXIS woodworking CNC Router. it is very easy to operate use Software to design and Export G code our machine could read. working area 1500mm*3000mm or 1300mm*2500mm custom sizes

Stone 4 Axis CNC router for Marble, Granite and Quartz tombstone.4th axis is Rotated spindle.heavy structure with water cycle(water circulation system)

Stone cnc router could engrave or carving on granite, marble, sandstone plate, jade, blue brick, red brick, ceramic tile, bluestone, crystal stone, microcrystal stone

4 axis cnc router with Rotary axis could work processing all cylinder stuffs like square legs or round legs according to your desgin from software.

5 Axis cnc router is update from 4 axis. 5 axis cnc are capable of simultaneously cutting five sides of a single material, thus extending the operator’s ability and flexibility.it helps to make moulds

Unique advantage for CNC router machine?

1. You can input image files, such as pcx, bmp, jpg, tip, etc., and use the computer for vectorization processing.

2. It contains 170 kinds of glyphs, which can describe, design and arrange any glyphs and graphics.

3. 3D curved surfaces can be made from 2D contours, the curved surfaces can be overlapped, automatically welded, and can be attached to any 3D patterns,

Graphics and text, for artistic sculpture.

4. Reverse engineering function. After receiving point information, it can generate corresponding surface for CAD work.

Produce CAM’s craftsman’s path and process it. If equipped with a laser scanning system, it can complete sample scanning and mapping to engraving.The whole process of processing and shaping is fast and precise.

5. Three-dimensional relief, 3D modeling of characters, animals and plants. After the image file is analyzed by gray level, curved surface,

Emboss documents, and carry out photo three-dimensional engraving processing.

6. Four-axis and five-axis machining can be upgraded. Using four axes, various embossing wheels can be manufactured from design to CAD/CAM.

7. Compatible with a variety of professional or special processing software, can read ICES, DXF and other data

Generate various high-precision tool paths.

Choose right CNC router&guild you order CNC router machine

There are lots of different CNC router over here.whydo you need CNC milling machine?Which type do you need?

if you have single specified work to do than it is very easy for you to choose right cnc router machine

if you have multi-works to do you have to think which point is more important. first of all because of Multi-works need to be done by 4 axis or 5 axis…Everyone needs know 5 axis cnc router is advanced technology with high price and also need operator have high professional techology.

basically you neeed take consideration as below:

What working area?X,Y Z axis. X axis means left to right. Y Axis means from front to back sides Z axis is Up or down.

It is very basic factor..customs size become more and more popular .surely there are some standard hot sales working size like 1300mm*2500mm or 1500mm*3000mm or 1200mm*1200mm 600mm*600mm

What is Z axis? Z axis decideds its thickness of your material?150mm or 200mm or 300mm or 400mm or 500mm or 650mm further more.being profesional supplier for CNC ROUTER we want to tell that The higher Z axis,the more un-stable when cnc Machine works.

what matieral do you work?

Hard wood?composite board?Acrylic?Aluminum?Brass?or stone?or something else.

we always received some doubts about big different price.They always asking us why Supplier A give me 5000usd dollars but Supplier B give me 7000 usd dollars?the Machine frame looks same completely from photo or vidoes and working video looks same completely.We would like to suggest you compare their detailed parameter not only looking frame(lath bed apperance) read them following tips.

1)spindle

The spindle is an important component of the CNC engraving machine, and its performance has a vital influence on the performance of the CNC engraving machine(CNC ROUTER). Machining spindles are usually divided into two categories: precision machining spindles and high-power cut-off spindles.

2) control system

using USB port to transfer data, the system has a memory capacity of more than 32M. As long as the file is saved, you can immediately leave the computer, turn off the computer, or perform other typesetting. This way greatly improves the working efficiency of the engraving machine.

there are lots of different control system so its price is difference. what control system you choose being professional supplier for CNC router(CNC engraving machine)We will give you suggestion..For now NCSTUDIO/RICOH NC DSP Remote for 3 AXis is more convient with very reasonable price for old aging operater which is not good at computer.However for young users prefer computer controlling machine to check how does G code path go directly on controllying system than they would use mach3 system.

For 4 axis CNC router or 5 Axis cnc router,if you want kinda of cheaper system than choose MACH3 .

if you get used to SYNTEC system than aim it

3) guide rail and balls crews

Large-format CNC engraving machine(CNC ROUTER) must use widened imported square guild rail, its load capacity and accuracy retention capacity are more than 30 times that of round rail, which ensures the high quality and high speed of the engraving machine.there are lots of different quality class for Square guild rails with its guild blocks. different quality class has very big price difference..

4) rack and pinion VS reduction gears.

Rack and pinion drives typically have a reduction gear so that the motor can run at a higher RPM where it has more torque. Typically reduction gears on industrial machines are around 5:1 on linear axes. These are usually durable and long-lasting, but can be expensive to replace.

biggest drawback of rack and pinion is gear pinion cannot work with its rack after 2 years or its belt pulley will get loose.it will make your machine works not perfectly for example cutting circle is not round.Normally speaking, different price between rack pinion and Reduction gears is 550usd dollars.

5) machine bed structure

As we mentioned at the begining on this page. Desktop frame/light frame/heavy frame.

6)Motion and motors( Stepper or Servo) what different from stepper to Servo?

Motors makes our CNC router machine moves. there are two option “STEPER”or “SERVO”

what difference between Stepping motor and Servo motor.

Steper is controlled by open-loop and Servo has its own encode so its closed-loop controlled.

Servo motor precision of CNC engraving machine is determinded by its encode.

The stepping motor precision of CNC engraving machine is determined by the number of phases and beats of the motor. If the number of phases and beats is higher, the accuracy is higher. that is why different brand motor whatever stepper or servo is different precision.

the output torque of the stepper motor will decrease as the speed increases. Engraving machine servo motor is a constant torque output, so it will not change strength because of speed.

Servo motors can accelerate in only a few seconds, so they are often used in situations where quick start and stop is required. The acceleration of the stepper motor takes hundreds of milliseconds, and the response time is much longer.

Servo motor has a strong overload capacity, encoder can finish automatic focusing according to the output, to avoid motor damaged due to overload. For stepper motor on CNC router If once overload, it is easy to damage to the stepper motor

7) do you need 3 axis,4 axis or 5 axis cnc router?

3 axis CNC woodworking engraving machine(CNC ROUTER) will move along with three axis

3 axis cnc router (woodworking engraving machine)are mainly used to cut flat two-dimensional parts(2D). its price could be acceptable for All users.

4 axis cnc router could finish 3D works its price is affordable for most of users.

In contrast to 4th axis cnc router it is 5 axis cnc router.

the 5-axis cnc machine can cut along two additional axes. These 5 cnc routers are capable of simultaneously cutting five sides of a single material, thus extending the operator’s ability and flexibility. it is very different 3 axis cnc machines., these machines are typically used to cut large three-dimensional parts. In addition, 5-axis engraving machines have higher gantry frames and longer X-axes, which allow them to cut larger parts; But 5 axis cnc machine is very expensive price than 3 axis or 4 axis cnc machines; The higher the gantry and the longer the X-axis, the less accurate and stable these machines are.

For proper quality control, gantry height and x axis length should be limited to the extent possible.

Although 5 Axis engraving machines may look like simple machines, they are highly complex technologies that require a certain amount of expertise to operate.

5-axis engraving machines tend to be more expensive than traditional 3-axis engraving machines, but ultimately provide greater flexibility, enabling users to be more creative with their designs.

In a word,being a buyer..You must check yourself what is your budget for this cnc machine projects?it is the most important factor.We hope this article could help you and avoid some wast time or saving money.

how to judge quality of CNC Router?how to test quality?

unexcept of its basic configuration like Software,motion system,or guild rails or spindle or something else.

please check following factors could tell what about machine quality.

1.Total Weight for machine bed.

if weight is very light than it is a toy or DIY machine can not put into industries processing works.

Let us analyse from its working principle of CNC router(CNC engraving machine)..Its work pattern is a keeping drilling or milling procedure with its material.than it request higher for stable bed.

if machine bed is light than The machine will shake during works processing..It must effect working precision bad.

2. Assembly accuracy.

You can not see any different with your own eyes about assembly accuracy from A machine to B machine.

you must turn on machine to test one by one to know how cnc router works precision.following some tips for your reference.

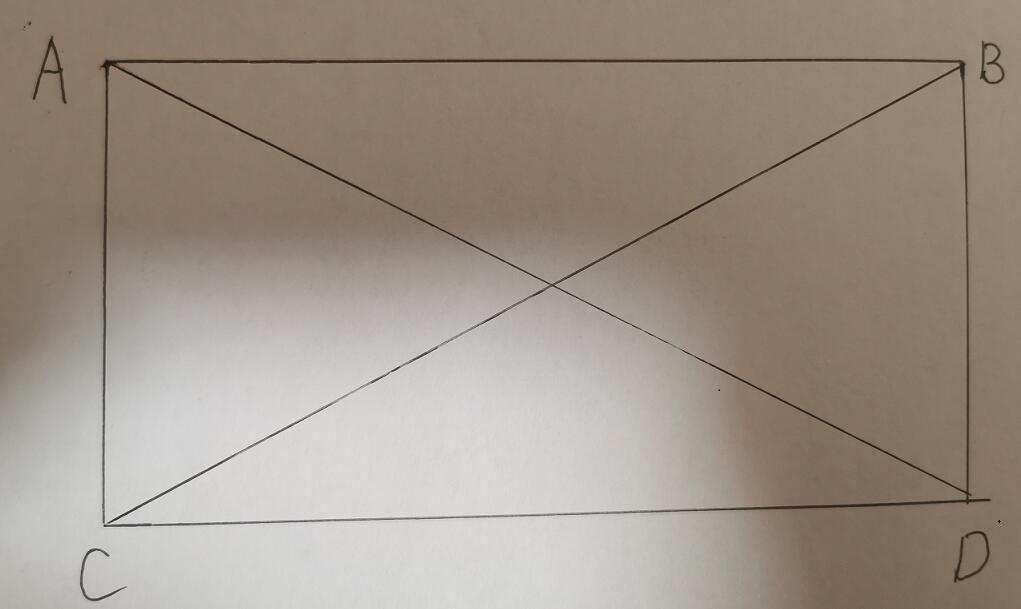

1)Perpendicularity between axis.

cut out bigger rectangular 1300mm*1000mm.

use software of cnc router to Export one larger Rectangular(1300mm*1000mm)and cut out and than use electronic caliper to measure its diagonal is same or not same(AD Line is equal to BC line)

the typical problem of the larger X,Y axis verticality is the rectangular diagonal is not equal.

Cut out triangle

Now we check the quality of interpolation. The rougher the surface is, the worse the interpolator and the drives operate.

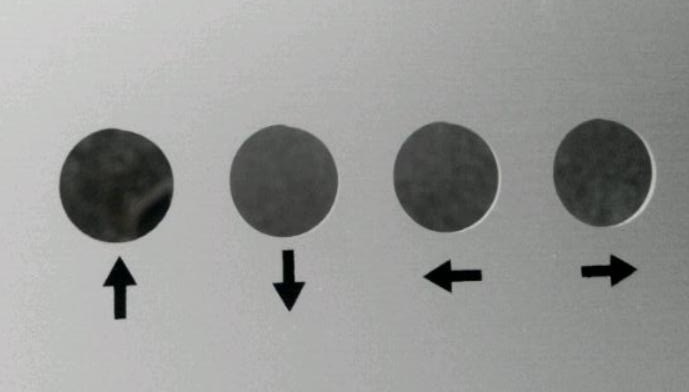

cut out circle.

We cut out cycle.we must pay more attention to its cutting speed and possible vibration

If its cutting speed is slower than cutting triangle or rectangle even though we setted same speed from software.which means that control system can not keep up with handling vector speed.flat surface is rough or any saw teeth.

Now we use Electroic caliper to measure cutting of circular wood from upper and lower surfaces it feels like”stair”means that spindle is not perpendicular to the work table.

if the circle is not round as below photo than means Z axis is not perpendicular to the axes X and Y.

How to maintain CNC router?How to prolong life of cnc machine?

All Machine is same as our human being.In order to keep all parts of CNC Router have good condition, it is very important to give regular maintenance. This can eliminate a lot of accident.

1.Check out everyday before starting the machine;

check if communication line, motor cable, optocoupler line is loose, voltage is stable;

Then turn on the power of the machine, operate the machine to move back and forth twice, and start working.

2. Clean the sensor (optocoupler, proximity switch) to prevent dust, powder and oil stains from sticking to the sensor, affecting its sensitivity or causing miscontact.

3. Clean the dust on the exposed guide rail (smooth rod), and clean it again with no.2 oil. After cleaning, add butter or no.2 lithium grease to lubricate them.

4. After the completion of a day’s work, take off the carving knife first, let the spindle,chuck, lock nut in a relaxed state.

This is helpful to extend the service life of spindle chuck. Then we began to clean the work surface, brush cleaning; Pay attention to the work surface is usually best not to accumulate sundries, lest the platform deformation.

5.spindle with water cooled

keep giving good conditon for clean cooling water cycle to Spindle , must not make the water-cooled spindle motor water shortage phenomenon,giving regular replacement of cooling water to spindle

water temperature is too high will damage spindle quickly , in order to giving circulating water as much as possible, you can change the large capacity water tank.

6. Move spindle stop at the lower left to prevent collision, and then cut off the power supply; Do not cut off power supply during CNC router works.it will damge us !!

7 if Your CNC router does not work for long time ..need we keep maintaince timely?

Yes. We need make machine run 1-2 times a week to extend life of components for CNC router.

especially in the rain season with large environmental humidity, make the CNC engraving machine empty operation for an hour.The heat generated by the electrical components is used to disperse the moisture in the NUMERICAL control system to ensure the stability and reliability of the electronic components.

8.Frequency converter(INVERTER) maintenance: the frequency converter(INVERTER) has been setted up well before shippment. It is forbidden to reset up and change cable without professional engineer’s guild.

so that damage of the motor or inverter by data input errors.

9. clean cable box regularly

Check whether the fans on the electric control box work normally, clean the dust in the electric control box regularly with a vacuum cleaner,and whether the screws on the wiring terminals are loose to ensure the safe of the electricity circuit

better to make door of cable box close to stop dusty,wood chips or metal powder geting into circuit board or electronic device.it is very easy to cause the insulation resistance declined between compents so that damaged these electronics.

10.maintance for Vacuum pump.

if your machine has vaccum pume don’t forget it.

We hope that every operator treat your cnc machines very well so that it has long time life to work for you.

basical Parameters for CNC router machine

Brand | Allwin cnc |

CNC MACHINERY | Ecnomic CNC ROUTER MACHINE |

Model for CNC ROUTER | 4040,6060,6090,1212,1325,1530 |

customs service | supporting 100% |

Motion and motor | Servo motion or stepping motion |

option accessories | Automatic tool changer;Rotary axis for cylinder works;5 AXIS CNC ROUTER |

TABLE | iron table or T-Slot aluminum or Vaccum T-Slot table |