Handheld Fiber Laser Welding Machine 1000W 1500W 2000W

- Home

- Products

- Laser Welding

- Handheld Fiber Laser Welding Machine 1000W 1500W 2000W

| Model: | 1000W/1500W/2000W for option. |

| Category: | portable handheld laser Welding machine |

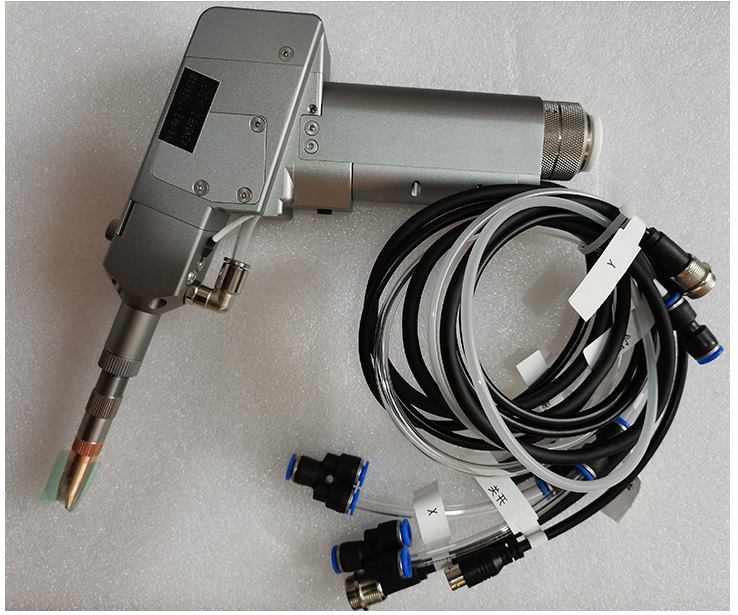

| laser head | wobble handheld welding head |

| laser welding generator | MAX/RAYCUS |

| cooling code | water cooled |

| Standard Price: | $7500.00 / Set |

| Price Range: | $7500.00 to $11000.00 / Set According to different laser power |

| working votlage | AC220V/380V 50HZ/60HZ |

| Payment Terms: | T/T,L/C |

fiber laser welder Introduction

Parameter for Portable handheld fiber laser welding machine

Desktop handheled laser welding machine is perforation, widely used in kitchen industrial , household appliances , advertisement , module industrial , stainless windows and doors , handiwork , home supplies, automobile spare parts industry.

The fiber laser welding machine speed can be 3-10 times faster than traditional welding,and the fiber laser welder can weld metal products of different materials and thicknesses, One machine can save at least 2 welders a year. It is very easy to operate. no need welding work license, Everybody can weld beautiful without a lot of experience.

Technical specification for Portable style fiber laser welding machine | |

Machine Name | Handheld Fiber Laser Welding Machine |

Laser Power | 1000W/1500W/2000W |

Laser Wave Length | 1080nm |

Laser Source | Raycus / JPT / MAX |

Fiber Length | 10M |

Cooling Mode | Water cooling |

Laser Pulse Frequency | 1-20HZ |

Pulse Width | 0.1-20ms |

Adjusted spot range | 0.1-3mm |

Minimum Welding pool | 0.1mm |

Gas source | 0.2Mpa (Argon ) |

Working Voltage | AC220V / 50Hz / 60HZ |

Gross Weight | 200KG |

| packing size | 1600mm*800mm*1200mm |

How To Choose Portable Handheld Fiber laser welding machine?

There are lots of different supplying for Fiber laser welding machine in the market with different quality.

there are lots of suppliers want to get orders then giving poor quality parts without any service technical support.

We Jinan Allwin cnc machinery Co.,ltd being a manufacturer’views.these information could help you to find a proper handheld fiber laser welding machine according to actual needs.

1. Firstly,What Vatts of Laser power do you choose?

500W,1000W,1500w,2000w is most popular.However,500W laser power is replaced by 1000W laser source.

Different metal thickness require different power of laser source.

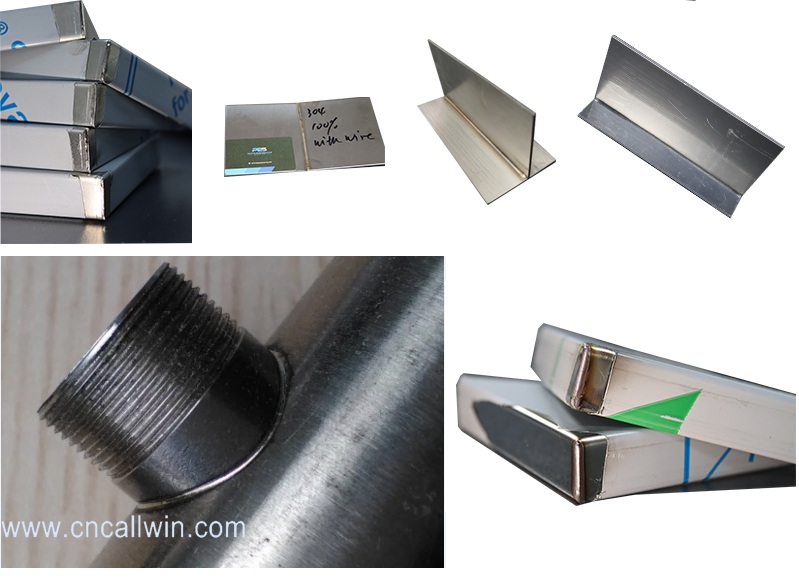

handheld laser welding machine Applications

Advertising industry: Fiber laser welder can weld copper, aluminum, stainless steel, galvanized sheet and other metal materials. Among them, galvanized sheet and other metal workpieces can be welded, which can replace traditional argon arc welding, electric welding and other processes.

Metal industry: It can weld copper, aluminum, stainless steel, galvanized sheet and other metal materials. Among them, galvanized sheet and other metal workpieces can be welded, which can replace traditional argon arc welding, electric welding and other processes.

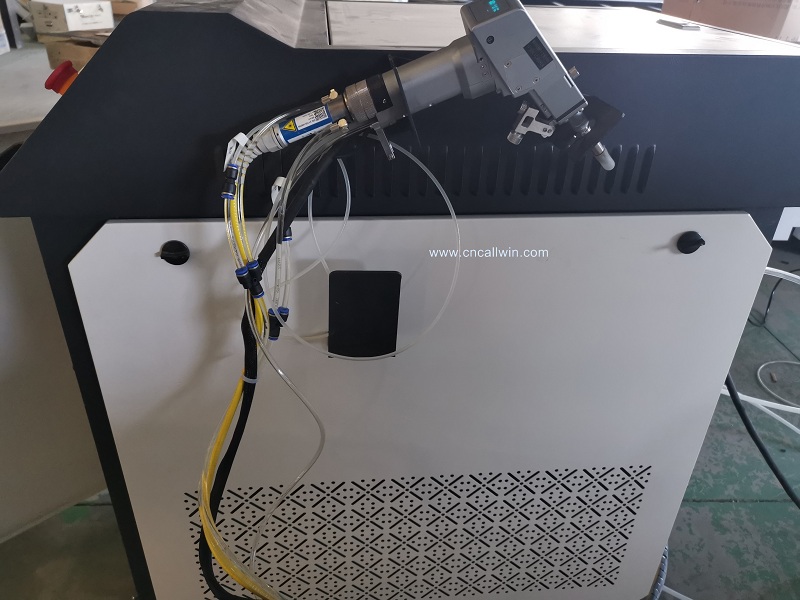

Detailed for portable handheld fiber laser welding machine

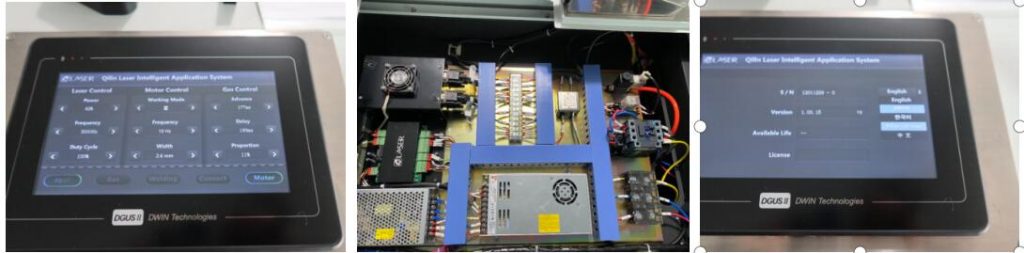

Tounch screen panel for portable handheld laser welding mahine

Easy to operate and learn..Interactive control system expand the tolerance range and welding width of the processing parts.It solves the disadvantage of minor laser welding spot and welding joints looks beautiful.

it support English language.

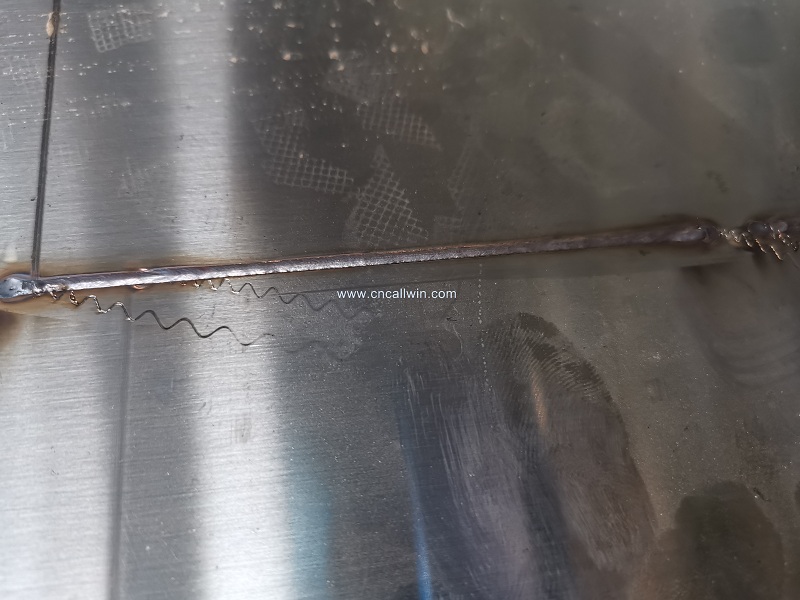

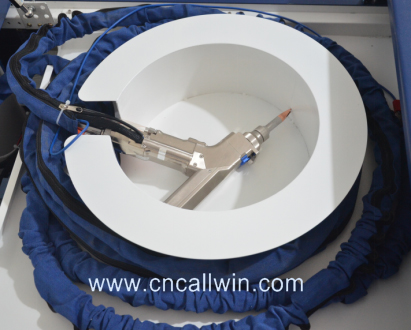

Auotmatic wire feeder: make option between Auto mode and manual mode

if gap is bigger than 0.5mm we need use feeder device.

if gap is 0.6mm then need use 0.8mm wire.

if gap is 0.8mmthen need use 1.0mm wire.

if gap is 1.0mm then use 1.2mm wire.

frequently asked question about Portable handheld laser welding machine

Q1:.How we choose the power?

1000W, 1500W.2000W is much more popular at the moment.

to advice what power to choose.please get to know following question before place order.

which kind of metal will you weld? what thickness of metal?what material exactly?Aluminum?stainless steel?

Q2:.What material can be weld by this machine?

A:Our fiber laser welding machine can weld stainless steel, carbon steel, aluminum.

Q3:.What kind of gas shall we use ?

A: Argon gas will be used, its function is to blow the dust during welding, and cooling cutting edge after welding.

Its another function is to prevent protect lens from burning during weldind.

Q4:Can we use other gas when welding, becuase Argon gas is expensive?

A: Argon gas is better.

Air can be used, but its welding effect is not good. If we use air, the welding edge will be black or yellow.

Q5:Which parts are spare parts?

A: Protect Lens, Nozzel are spare parts.

Q6:How long does the nozzle should be replaced?

A: The nozzle are consumable part, it should be replaced near half of month to two months according to your welding quantity.

Q7:How long does the protect lens last?

A:if it is in normal use, it can keep near one week.

Sure, it is up to the material what we weld, if we weld carbon steel, there are jump slags during welding, the jump slag is easy to burn the protect lens.

Q8:How long does one jar of gas weld?

A: One jar of argon gas can weld 4 days if we weld 8 hours continuely per day.

Q9:How many pcs of protect lens and nozzle do you recommend for one year?

Consumable Parts:

Protect Lens: USD2 / PC recommend 100-200 pcs per year

Nozzle: USD5.5/PC recommend buy 30-50 pcs per year

Q8:Shall we choose wire feeding device or not?

A: if the gap is within 0.5mm, don’t need use wire feeding device.

Wire feeding device must be selected if the gap is more than 0.5mm,

if gap is 0.6mm, use 0.8mm wire,

if the gap is 0.8mm, use 1.0mm wire

if the gap is 1mm use 1.2mm wire,

if the gap is 1.2mm, use 1.4mm wire,

if the gap is 1.4mm, use 1.6mm wire.

We hope it could help you out.

What is difference between handheld laser welder and traditional mig/mag/TIG welder?

Why lots of people would like to spend more money buying laser handheld welder? are they crazy?

No.they are not crazy.it is very correct action beacause of hand held laser welder could work more than traditional welder.

1)Wider application of materials

The laser hand-held welding machine can weld various metal materials so that its another name is Multi-functional welding machine or universal welding machine.

Stainless steel;copper or brass;Aluminum and aluminium alloy

fiber laser welding machine could work more than above we metioned..its obviously characters is could welding together between dissimilar metals.the researches shows that the application of Cooper brass Nickel titaninum-Molybdenum,brass lower carbon steel other dissimilar metals can ben finished at certain condtions.

2)Easy to operate handle laser welder&easy to learn

traditional welding professional workers is very costly.and it needs time to learn and master these welding skills.

However,Hand held laser welding machine does not request high.it is very easy to learn and master.it does not require professional qualifications.that will help enterprise down labor cost.

3)Welding speed is faster than 4-10times.

it has less pollution to the environment and less harm to people

;to some extent that the welding speed is fast, 4-10 times that of the traditional welding machine, saving 3-5 professional welders. It has little effect on the physical and chemical properties of welding materials. During the laser welding process, energy is concentrated, the thermal deformation of the workpiece is small, the weld seam is beautiful, the weld is deep, the strength is high, and thinner materials can be welded.

3)Portable hand held fiber laser welding machine could weld any metals like aluminum copper.

its so called Multi-work welding machine

Let us summarize that why more and more workshop would rather buy expensive welding machine than Traditional MIG/TIG welding machine here

traditional MIG/MAG/TIG/welding machine request high professional techical staff with qualiifed certificate.which caused high wages,and welding speed for traditional ways is kinda of slow.

Traditional welding machine will bring workpieces deformation with large thermal effects and traditional welding machine could have Irregular welding seams.We have to polish twice after works..

it is more much advantage to weld thin materials..

portable handheld fiber laser welding machine is so called multi-work welding machine