Laser Cutting Manufacturer

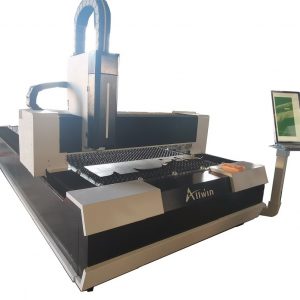

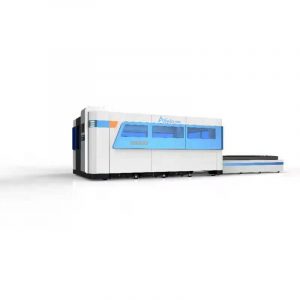

ALLWIN CNC manufacturing quality fiber laser cutting machine which is a kind of thermal cutting with factory price and free support from China.

Laser cutter uses a focused high-power laser beam to irradiate the workpiece to quickly melt, vaporize, ablate or reach the ignition point of the irradiated material.

Affordable Fiber Laser Cutting Machine China Supply

Fiber laser cutting machine fast techinical support

The molten material is blown away by the high-speed airflow coaxial with the beam. In this way, the workpiece can be cut apart.

so far we have two different laser cutter machine

Fiber laser cutter& Co2 laser tube cutting machine

how choose Fiber laser cutter?

there are lots of clients who interested in fiber laser cutting machine but they feel confused in face of so many different type of fiber laser machines.here it is our suggestion:

What is your budget?

what working area?

What thickness of your metal sheet?

what material exactly do you cut?

how does laser cutter work

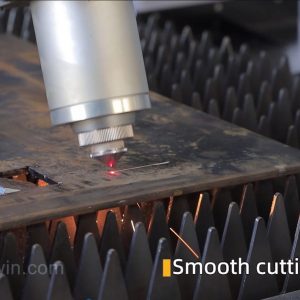

How a laser cutter works?In laser cutting, the horizontal laser beam emitted by the laser turns into a vertical downward laser beam through a 45° total reflection mirror, and then is focused by a lens to form a very small spot at the focal point. When the spot is irradiated on the metal material, the metal material is quickly heated to the vaporization temperature and evaporates to form a hole. As the beam moves on the material, and with auxiliary gas (carbon dioxide gas, oxygen, nitrogen, etc.) to blow away the molten waste, the hole continuously forms a very narrow (such as 0.1mm or so) cut the seam to complete the cutting of the material.

why use fiber laser cutting machine?

1.The cutting quality is good.

A. The laser cutting incision is narrow, the two sides of the incision seam are parallel and perpendicular to the surface, and the dimensional accuracy of the cut parts can reach ±0.05mm.

B. cutting surface is smooth and beautiful, the surface roughness is only tens of microns, and even laser cutting can be used as the last process without mechanical processing, and the parts can be used directly.

C. After the material is laser cut, the heat-affected area is small, the performance of the material near the slit is almost unaffected, and the workpiece has small deformation, high cutting accuracy, and regular cut surface.

2.High cutting efficiency

Due to the characteristics of the laser, the laser cutting machine is generally equipped with multiple numerical control worktables, and the entire cutting process can be fully numerically controlled. During operation, you only need to change the numerical control program to complete the cutting of different graphics, which can be used for two-dimensional cutting and three-dimensional cutting.

3.Fast cutting speed

Using a laser with fiber laser power of 1200W to cut 2mm thick low-carbon steel plates, the cutting speed can reach 600cm/min; for 5mm thick polypropylene resin plates, the cutting speed can reach 1200cm/min.

the fastest cutting speed upto 40 meters per minutes, cutting speed for fiber laser cutter is much faster than linear cutting machine.

4.Non-contact cutting mode.

There is no contact between the torch and metal workpiece during laser cutting, and there is no tool wearing. Processing parts of different shapes does not need to change the “tool”, just change the output parameters of the laser. The laser cutting process has low noise, low vibration and no pollution.

The electro-optical conversion efficiency of the fiber laser cutting machine is above 30%.Low-power fiber lasers do not need to be equipped with a cooler.Air cooling can greatly save energy during work, reduce operating costs, and maximize production efficiency

5.The operation and maintenance cost of fiber laser cutting machine is the lowest

during fiber laser cutter works, laser nozzles or protection lense is needed, and no additional gas is needed to generate the laser; the laser adopts a semiconductor modular and redundant design. There is no optical lens in the resonant cavity and no start-up time is required. It has the advantages of adjustment-free, maintenance-free, and high stability, which reduces the cost of accessories and maintenance time, which is unmatched by traditional lasers. The light of the whole machine is transmitted by optical fiber source, and there is no need for complicated light guide systems such as mirrors. The light path is simple, the structure is stable, and the external The optical path is maintenance-free; the cutting head includes a protective lens to minimize the consumption of expensive consumables (such as focusing lenses).

6.The output wavelength of the fiber laser is 1.064 microns, which is 1/10 of the CO2 wavelength.The output beam has good quality and high power density, which is very conducive to the absorption of metal materials. It has excellent cutting capabilities.

7.The operation of the fiber laser cutting machine is simple. The light is output through the fiber, which makes the design of the mechanical system very simple; after the laser is equipped with a shutter, it can be divided into multiple devices by the fiber, and divided into multiple channels and multiple units to work at the same time. Convenient function expansion, convenient and simple upgrade.

8.Saving material&avoid making mould

CNC fiber laser cutter use COMPUTER numerical control programming and typesetting, different shapes of products can be cut and disassembled, maximize the utilization rate of materials.the fiber laser cutter will cut according to your design from autocad or other design software supported.

Fiber laser cutting machine does not need mould making.

9.Advantages compared with YAG laser cutting machine:

A. fiber laser cutting machine has Faster cutting speed: The speed of fiber laser cutter is 4-5 times that of YAG, which is suitable for mass processing and production.

B. Lower operating cost: The operating cost of fiber laser cutting machine is lower than that of YAG solid laser cutting machine.

C. The highest photoelectric conversion efficiency: The photoelectric conversion efficiency of fiber laser cutting machine is about 10 times that of YAG.

10. The advantages of fiber laser cutter compared with CO2 laser cutting machine:

A. Fiber laser cutting machine has excellent beam quality: smaller focused spot, thinner cutting line, higher work efficiency, and better processing quality;

B. The cutting speed of fiber laser cutting machine is extremely high: 2 times that of the same power CO2 laser cutting machine;

C. The fiber laser cutting machine is extremely stable: the world’s top imported fiber laser is used, with stable performance, and the service life of key components can reach 100,000 hours;

D. Fiber laser cutting machine has extremely high electro-optical conversion efficiency: the photoelectric conversion efficiency of fiber laser cutting machine is about 30%, which is 3 times higher than that of CO2 laser cutting machine, which is energy-saving and environmentally friendly;

E. The use cost of fiber laser cutting machine is extremely low: the power consumption of the whole machine is only 20-30% of that of similar CO2 laser cutting machines;

F. The maintenance cost of fiber laser cutting machine is extremely low: no laser working gas;fiber transmission, no reflective lens;can save a lot of maintenance costs;

G. The fiber laser cutting machine is easy to operate and maintain: fiber transmission, no need to adjust the optical path;

H. Fiber laser cutting machine has super-flexible light guiding effect: small size, compact structure, easy to flexible processing requirements.

What are the disadvantages of laser cutter

Laser cutting is limited by laser power and equipment volume. Laser cutting can only cut metal plates and pipes. As the thickness of the workpiece increases, the cutting speed is significantly reduced. In addition, the cost of laser cutting equipment is high and the one-time investment is large.

that is why some smaller workshop hesitate considering buying fiber laser cutter.Jinan allwin cnc machinery will help you to choose afforable fiber laser cutting machine according to your details works projects or metal fabrication subjects.

what is a laser cutter used for

Fiber laser cutter application.Most of fiber laser cutting machines are controlled by a numerical control program. In the field of automobile manufacturing, laser cutting machines are used to cut and process car roof windows. German Volkswagen uses laser cutting machine equipment to cut complex-shaped body sheets and various curved parts. In the aerospace field, laser cutting machine is used to process aerospace parts, engine flame tubes, titanium alloy thin-walled receivers, aircraft frames, titanium alloy skins, wing truss, tail wall panels, helicopter main rotors, and space shuttle ceramic partitions. Construction machinery and agricultural machinery industry, advertising industry, sheet metal processing industry, automobile industry, chassis cabinet production, spring sheet production, subway accessories, elevator manufacturing, furniture and kitchenware manufacturing, etc.

what material does fiber laser cut??

A variety of metal plate,metal pipe,mainly suitable for stainless steel,carbon steel alloy steel,sillicon sheet,

Aluinimum alloy,aluminum,galvaized plate,zinc plate,pickling plate,cooper,silver.

kindly note:Different material request different power for fiber laser source. like cooper needs professional laser source.

how much does a laser cutter cost

How much is a laser cutting machine?how much is a laser cutter? Generally speaking, the price of a fiber laser cutter is between US$10,000 and US$250,000, depending on the brand and configuration of the fiber laser equipment.

Factors affecting the price of laser cnc include brand, hardware configuration, service and other factors. Among them, the most important factor affecting the price is the hardware composition.The following list has a greater impact on the cost of the cnc laser cutter:

①Gantry structure: including bed, worktable, beam, XYZ axis moving mechanical parts (servo motor drive, reducer, etc.).working area 1.5m*3m/1.5m*6m/1.3m*0.9m.

②Laser generator: There are single-module and multi-module lasers. Usually single-mode below 3kw is mostly single-mode, and above 4kw is mainly multi-module. China brand Raycus,Max is famous and stable in the market at very affordable price.

③Laser cutting head: The laser cutting head has manual focusing and automatic focusing. The price difference is relatively large. Generally, manual focusing within 2kw is cost-effective, and automatic focusing is more efficient than 2kw.There are lots of different brand Laser head in the market.but We prefer Raytools laser head to other brand.

Laser head is as main products for fiber laser cutting machine how does it work effect to how laser cutting machine works..

④ Numerical control system: It is the job of controlling the movement track of XYZ axis, the output power of the laser and the cutting method.

⑤Water cooler: cools the laser and cutting head, and the chiller keeps the laser and cutting head in the normal working temperature range to avoid equipment loss caused by high temperature quotation.

⑥: Gas supply system: usually there are auxiliary gases such as compressed air, oxygen, nitrogen, argon, etc., whose function is to improve the cutting quality.

⑦: Voltage stabilizer: the function is to stabilize the voltage and avoid unstable voltage and affect the cutting effect.

The above list is the main components that affect the laser cutting machine. Therefore, for those who do not know about cnc laser cutter, when purchasing laser cutter, You must inform the salesperson of the materials to be cut, the thickness of the materials, the proportion of various materials, and the length of work per day. Of course, if you know the power of the cnc laser you want to buy with certainty, then tell the salesperson directly. In addition, when buying a metal laser cutter, price is one aspect. After-sales service and cost performance are equally important. I hope you don’t encounter situations where you only sell equipment without providing services. Finally, I wish you a prosperous business.

how to build a laser cutter?what parts does laser cutter includes?

cnc laser cutter has many advantages. Many people want to build it by themselves.Manufacturing fiber laser cutting machine requires several steps: One. Hardware procurement preparation; Two. Hardware assembly; Three. Parameter setting; Four. System debugging;Five. Machine test Operation; Six, machine delivery, data transfer.

Today we only talk about the main hardware parts, and we will introduce other parts in further detail in the future.

The main components of fiber laser cutting machine

- 1.Fiber laser Generator

- Laser generator is the core “power source” of fiber laser cutting machine. Just like a car engine, it is also an expensive component in a fiber laser cutting machine. Currently there are fiber lasers such as IPG, ROFIN, RAYCUS, etc. on the market.

- Motor

- The motor of the fiber laser cutting machine is the core component of the motion system. The performance of the motor directly affects the effect of product processing and production efficiency. At present, the commonly used motors are servo motors. Configure according to the industry type and product type of the cutting object. We will advice what power of Yasakwa motor according to different fiber laser source.

Our Fiber laser cutting machine use Japanese Yaskawa servo motor and driver.

- Stepper motor:

Fast start-up speed, sensitive response, suitable for low-demand cutting. The price is lower. There are many brands of stepper motors with different performances. Now lots of companys to attractive customers at cheapest price they use stepper motor and driver.being a honest supplier,We would like to advice you stop using stepper motor or driver on fiber laser cutting machine.

- Servo motor:

- High motion, stable motion, high load, stable performance, smooth edges of processed products, fast cutting speed, high price, suitable for industries and products with high cutting requirements.

- Fiber laser cutting head

The fiber laser cutting head is a laser output device, which consists of a nozzle, a focus lens and a focus tracking system. The cutting head of the fiber laser cutting machine will walk according to the set cutting track, but the height of the laser cutting head needs to be adjusted and controlled according to different materials, different thicknesses, and different cutting methods.

- Laser lens Laser lenses are mostly used in the entire fiber laser cutting equipment. Many optical devices contain laser lenses. Different lenses have different functions, such as total reflection lens, semi-reflective lens, focusing lens, etc. The quality of the lens directly affects the output power of the laser, and also affects the performance of the entire fiber laser machine.

- Host workbench

The bed, beam, worktable, and Z-axis system of the fiber laser cutting machine are collectively referred to as the host. When the fiber laser cutting machine performs cutting, first put the workpiece on the bed, and then use the servo motor to drive the beam to control the movement of the Z axis. Users can adjust the parameters according to their needs.

- Rack

Fiber laser cutting machines have very high requirements for machine stability. At present, the mainstream shelves on the market include gantry type, cantilever type, beam type, etc. Different shelves have different functions. For example, the beam frame is mainly used for material cutting of large manufacturers. There are also models for specific fields, such as three-dimensional fiber laser cutting, which are mainly used in the automotive industry.

- Chiller

The chiller is the cooling device of the fiber laser cutting machine, which can quickly and efficiently cool the laser, spindle and other equipment. The current chillers are equipped with input and output control device switches, as well as advanced cooling water flow, high and low temperature alarms and other functions, and their performance is more stable.

- CNC fiber laser cutting system

The control system is the dominant operating system of the fiber laser cutting machine, which mainly controls the machine tool to realize the movement of the X, Y, and Z axes, and also controls the output power of the laser. Its quality determines the stability of the operating performance of the fiber laser cutting machine. Through software control, the cutting effect can be improved.

- Gas supply system

The gas supply system of fiber laser cutting machine mainly includes gas source, filter device and pipeline. Among them, the air source has two kinds of bottled air and compressed air. The auxiliary gas blows away the slag when cutting metal, plays a role in supporting combustion, and also has a certain protective effect on the cutting head.

- Other parts Air-cooled dryer and filter: used to provide clean and dry air to the laser generator and beam path to keep the path and reflector working properly.

- Ventilation dust collector: suction and filter the smoke and dust generated during the processing, so that the exhaust gas can reach environmental protection standards.

- Slag discharge machine: remove leftovers and waste generated during processing.

- Stable power supply: The power supply is connected between the laser, CNC machine tool and the power supply system. Mainly play a role in preventing external power grid interference.

how to maintain fiber laser cutter?how to prolong life of laser cutter?

How to maintain a laser cutter? How to extend the service life of laser cutting machine? Every day before and after operating the fiber laser cutting machine, some maintenance work must be done to extend the service life, so how to do the daily maintenance of the fiber laser cutting machine? When using a fiber laser cutting machine to process objects, you need to learn the equipment use and maintenance skills of the fiber laser cutting machine in order to better play the efficiency of the equipment and maximize the efficiency of the equipment.

- First of all, the operator must be trained, familiar with the structure and performance of the equipment, and master the knowledge of the operating system. Follow the rules of the cutting machine and operate safely and independently. Of course, if any mechanical equipment wants to be used for a long time, maintenance is the first element. If you do not pay attention to maintenance, the best equipment will not be durable. Then the maintenance of fiber lasercutter is mainly concentrated in the following 6 aspects:

- Maintenance of the lens

- Before starting the laser cnc, check the mirrors 2 and 3 to check whether there is dust on the mirror surface or whether the mirror surface is damaged. The maintenance of the lens of the laser cutting machine is very important, and it is very important to ensure the quality of the beam.

The lens of the laser cutting machine is easily contaminated by smoke and dust. It is recommended to clean it once a day before starting work. Generally, anhydrous industrial alcohol acetone is used to clean the lenses. Different lens cleaning methods are different. When the mirror surface is flat and there is no lens holder, use lens paper to clean; when the mirror surface is curved or the mirror surface has a lens holder, please clean it with a cotton swab.

When using the lens, pay attention to focusing the lens, protecting the lens, QBH head and other optical surfaces, and do not touch it directly with your hands to prevent scratches or corrosion of the lens.

- Maintenance of the cutting head

Before using every day, check whether the laser is emitted from the center of the nozzle, if not, please readjust the calibration.

Before cutting, adjust the height of the cutting head to a suitable drilling position.

When cutting, always observe whether it is cutting. If you do not cut, first raise the cutting head by hand to stop cutting, check whether the cutting parameters are correct, whether the nozzle and the protective mirror are damaged, adjust them, and then return to the uncut state, and then continue cutting.

When cutting, observe whether the cutting piece is turned over or up. If so, take over when the cutting head collides with the workpiece. If the plate is not flat, adjust it to the appropriate drilling height (3-5mm) at any time.

When cutting, observe whether the cutting head catches fire. If it catches fire, stop cutting, check whether the nozzle is worn, and judge whether the focus is changing. If so, increase or decrease the pad according to the situation.

- Chiller maintenance

The chiller is used as the cooling equipment of the fiber laser cutting machine. The chiller guarantees the normal operation of the fiber laser cutting machine at a constant temperature. Pay attention to the water temperature when working for a long time. It is recommended that the water temperature be below 35 degrees; in winter, the circulating water should be prevented from freezing and the laser tube from freezing and cracking (antifreeze can be added).

The water inside the chiller needs to be replaced regularly, because long-term use is prone to scaling and reduces the cooling effect. Generally, clean the chiller 1-2 times a month, replace the internal circulating water, and use distilled water without impurities, such as pure water or mineral water. But be careful not to use tap water.

- Maintenance of the guide rail frame

Each rail rack needs to be cleaned regularly to remove dust and other debris to ensure the normal operation of the equipment. The frame should be wiped and lubricated frequently to ensure that the lubrication is free of debris.

In addition, always check the steel belt to ensure that the steel belt is tight. Regularly check the straightness of the track and the verticality of the machine. If abnormalities are found, maintenance and adjustments will be carried out in time, usually at an interval of 6 months.

- Attention to the working environment

The environment where the machine is located must be pollution-free, free from interference and influence from strong electricity, strong magnetism, etc. Pay attention to anti-vibration and anti-loose: the cutting machine is particularly sensitive to vibration. The working environment should be far away from places with vibration sources such as punches and heavy objects. If the connection is loose, it is recommended to install anti-vibration pads and re-reinforce it.

In addition, pay attention to anti-interference and anti-leakage: the electromagnetic environment of the cutting machine mainly includes the surrounding electromagnetic field, the quality of the power supply, and the interference of signal electrical noise.

- Daily maintenance requirements

- Check and clean the workbench every day to keep the laser and laser cutting machine clean and tidy.

- Check whether the X, Y, and Z axes can return to the origin every day, and check whether the position of the striker of the origin switch is offset.

- Check whether the connecting wire is tight and disconnected every day, and check whether the fan of the control box is normal.

- Clean the X-axis screws and Y-axis screws every week, and then add oil.

- Check whether the fixing screw of the screw nut is damaged, and whether the joint between the water pipe and the air pipe is damaged or blocked.