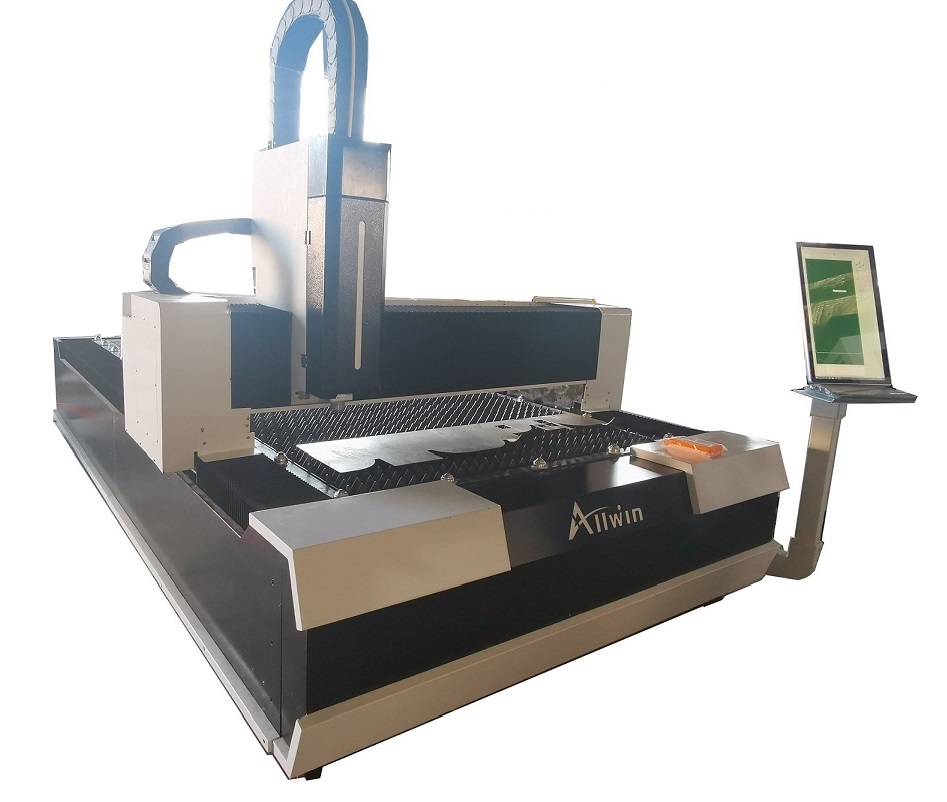

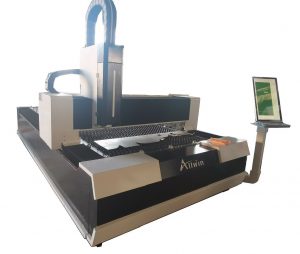

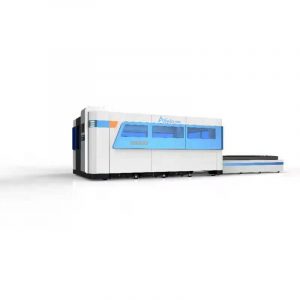

2000W Laser Cutting Machine

- Home

- Products

- fiber laser

- 2000W Laser Cutting Machine

why china fiber laser cutting machine become hot sales?

With the development of laser equipment, the power of optical fiber laser cutting machine is increasing. At present, the power of laser cutting machine on the market is from 1000W to 12000W, and the minimum power is 1000W.500W fiber laser cutting machine is not popular any more.

2000W laser source is most cost-efficient.that is, affordable price for middle workshop or smaller facotry.in aditional,2000W fiber laser cutting machine does not need too much use maintance and its work is pretty stable.

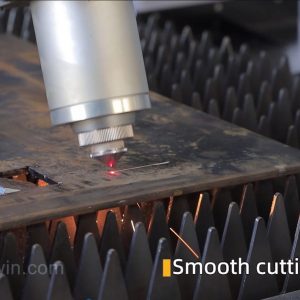

high precision cutting and its fast cutting speed, the effect of cutting surface is small.that is why fiber laser cutter become popular.

2000W Laser Cutter machine Introduction

| Model: | 3015/2513/1390 |

| Category: | 2000W Laser Cutting Machine |

| Views: | 1766 |

| Brand: | Allwin cnc |

| working area | customs |

| Standard Price: | $19000.00 / Set |

| working area | 1500mm*3000mm |

| Supply Ability: | 50 Sets / Month In stock! From – Jinan allwin cnc machinery co.,ltd |

| PaymentTerms: | T/T,L/C |

mainly component of fiber laser cutting machine

2000W Fiber laser generator Max,Raycus,IPG for option.

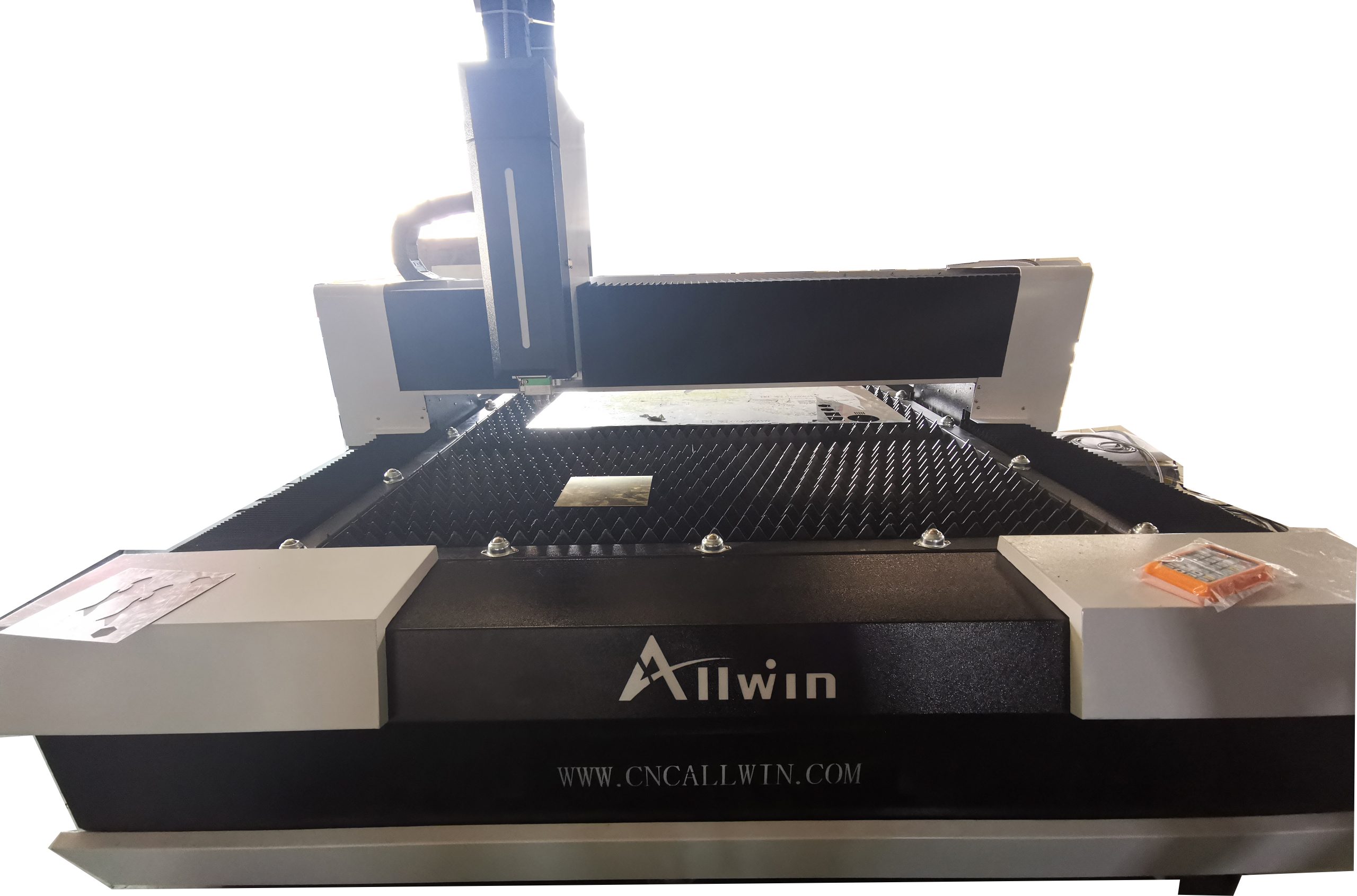

automatic focus laser cutting head–Swiss Raytools brand.

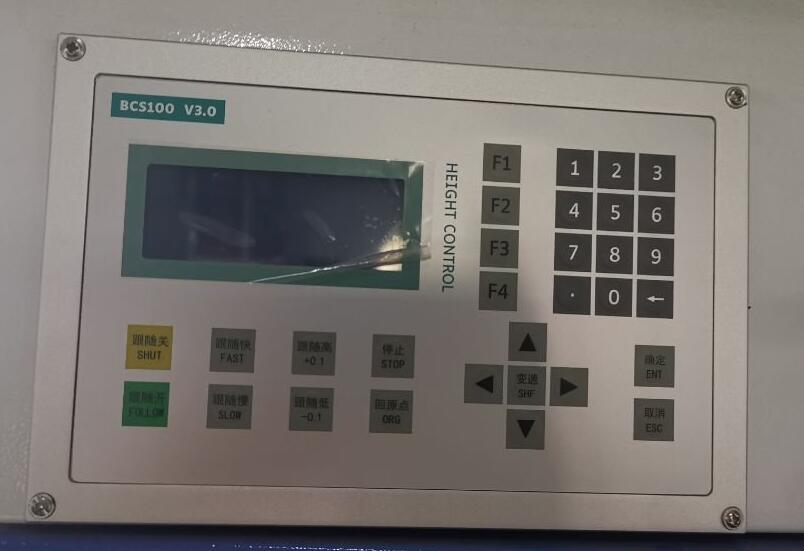

CNC control system—manage working condition and movement of laser cutter on the three axes,

CNC control system control some output power of the laser

Voltage stabilizer(voltage regulator)—Playing a very important roles among power supplying system,CNC machine and laser generator.keeping giving stable voltage fiber laser equipment make machine works stable so that achieve beatiful cutting result.

if Your supplying voltage is not stable it will harm to laser generator or CNC machine components.

water cooler

Independent electronic cabinet–it is avoid singal interference and heat dissipation good

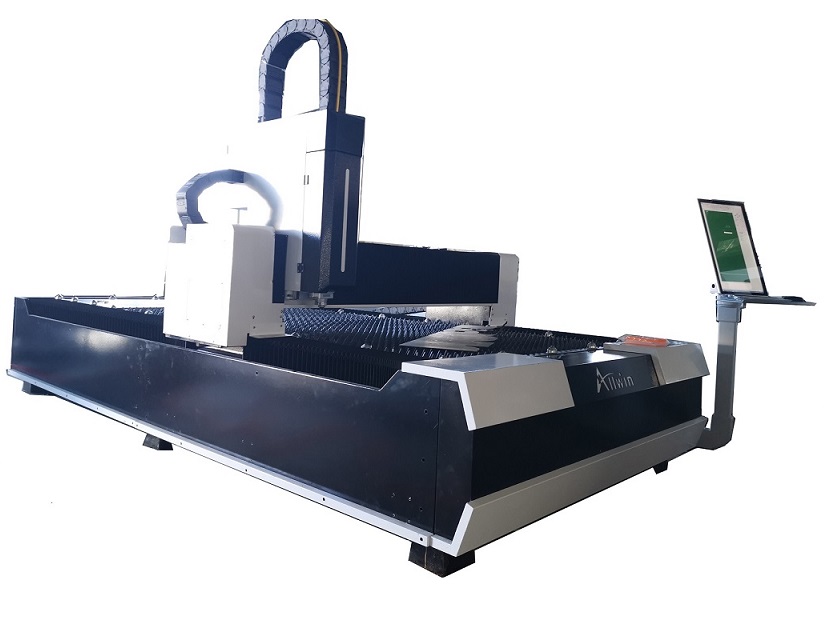

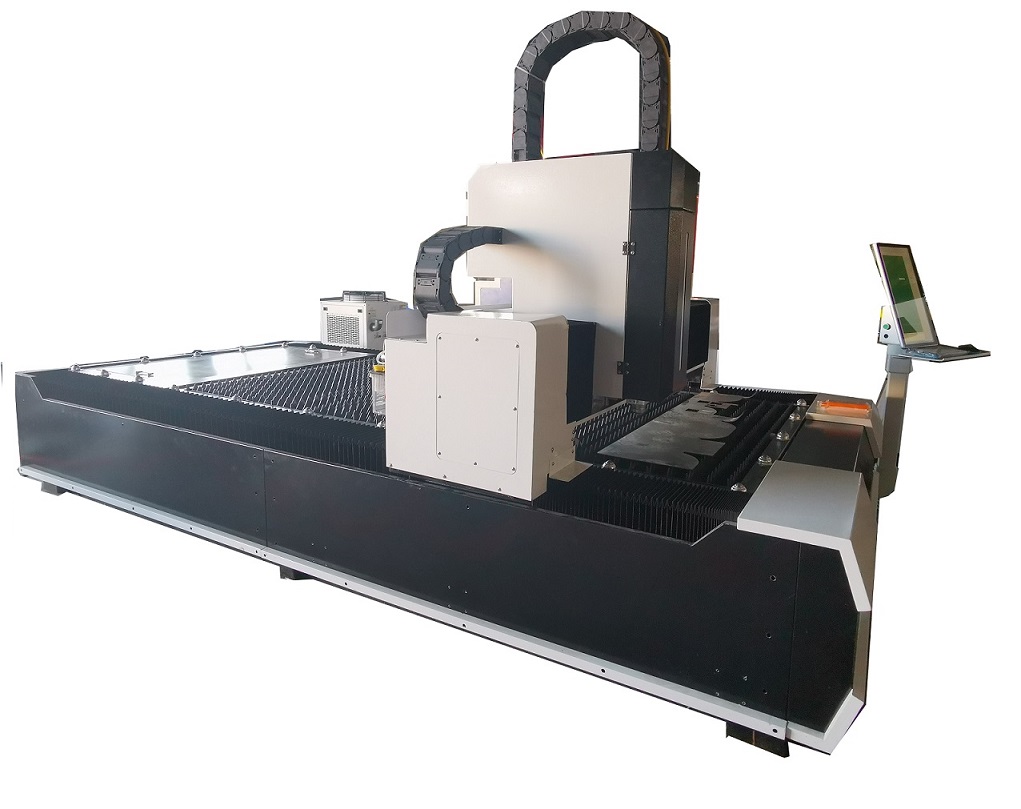

Heavy frame machine bed with Aviation aluminum gantry could make machine moves faster.

Gas tank/ gas bottle/gas cylinder

gas bottle or gas tank to supply working medium gas or auxiliary gas to fiber laser cutting machine.

if you don’t have too much budget than please ignore dust removal system or slag discharging machine

dust removal system is used to extract and filter the smoke and dust generated during processing to make the exhaust gas discharge in line with environmental protection standards.

Slag discharging machine, is used to exclude some of the remaining waste in processing and some expected garbage corners, the main role is to clean up garbage

Conclude:

metal fiber laser cutting machine includes many different parts..How quality for their parts determine how machine works.

We must be careful to check them before order machine.

2000W fiber laser source Max,Raycus and IPG for option

Machine tool workbench with sawteeth

High precision

fiber laser cutting machine designed with Ultra-high pressure tensile integrated beam improved the rigidity of the gantry beam, light weight for gantry to move faster

why 2000W Fiber Laser Cutter?guild to buy metal fiber laser cutting machine?

What material could fiber laser cutter cut?

Laser cutting machine has been used in many industries, there is a large space for development. in spite of this, there are still a lot of friends do not know how to laser cutting function to cut what material and metal fiber Laser cutting machine is mainly aimed at a kind of cutting metal, is a kind of thermal cutting, mainly cutting the following kinds of metal materials such as:

1.)Stainless steel

if you could accept oxidation on cutting end face than use Oxygen gas.

If You don’t like its axidation surface than use Nitrogen…its burn-free edge,don’t need further treatment

Here it is another tips for cutting stainless steel.Coating oil film on the surface of the sheet can obtain better perforation effect without reducing the processing quality

2)Titanium

Titanium plates are cut with argon and nitrogen as processing gases.

metal fiber laser cutter can cut a lot of material, the scope of application is also very wide. Laser cutting as an accurate processing method, can cut almost all materials, including thin metal plate two-dimensional cutting or three-dimensional cutting.as we could see In the field of automobile manufacturing, the cutting technology of space curve such as car roof window has been widely used. Volkswagen of Germany uses laser with power of 500W to cut the body sheet and various curved parts of complex shape.

3)brass,coopper Or Aluminum

Character of brass or cooper is high reflectivity and very good thermal conductivity.

So if your work mainly is to cut Copper or brass..You must inform us supplier in advanced so that we suppliers could add “Reflection-absorption”device to our Software system.otherwise the reflection will destroy the optical components

For its high reflectivity,its cutting ability is much weaker than carbon steel or stainless steel.

if thickness of Brass or copper is less than 1mm you need Nitrogen.

if thickness less than 2mm you need oxygen gas.

Compared to Copper or brass.it is very easy to cut aluminum at same power for fiber laser generator..it is better use Nitrogen to cut Aluminum than Oxygen gas. using oxygen to cut aluminum its cutting surface looks rough and hardness.

2000W laser cutter applied industries

The 2000w fiber laser cutting machine can be used for plane cutting and bevel cutting, and the cut surface of the workpiece is neat and smooth. It is suitable for high-precision cutting processing such as metal plates. It is used in sheet metal processing, aviation, aerospace, electronics, Electrical appliances, subway accessories, automobiles, food machinery, textile machinery, engineering machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, metal external processing, kitchenware processing and other manufacturing processes industry.

what materials can the fiber laser cutter cut?

The fiber laser cutting machine is deeply loved by professionals due to its good cutting performance. What materials can the fiber laser cutting machine cut?

To figure out what material the fiber cutting machine can cut, we must first understand the working principle of the fiber laser cutter. The fiber laser cutting machine uses a fiber laser to output a high-energy and high-density laser beam to achieve cutting of various materials. The absorption effect of the laser beam is good, so the fiber laser cutting machine is widely used in the field of metal cutting.

So which metal materials can fiber laser cutting machine cut? Fiber laser cutting machine can cut most metals and their alloys. Based on years of work experience, extensive applications and experimental results, the fiber laser cutting machine has a good cutting effect on the following materials:

- Carbon steel, stainless steel

The current laser cutting machine can cut carbon steel plate with a cutting thickness of up to 30mm. Using fiber laser cutting machine, the width between the cuts can be controlled within a relatively small range, and the slit for thin plates can reach about 0.01mm.

For stainless steel materials, fiber laser cutting machine is an effective cutting tool. When cutting stainless steel, there are many advantages, such as smooth cutting surface, small kerf, fast cutting speed, small thermal deformation, and the ability to maintain stable chemical and physical properties of the material. Due to the stable chemical properties of stainless steel, flame cutting is not effective for stainless steel. Therefore, laser cutting and plasma cutting are usually only used for stainless steel cutting, but laser cutting is higher than plasma cutting in terms of cutting quality.

- Nickel and its alloys

Nickel-based alloys are also called super alloys, and there are many varieties. Most of them can be cut by a fiber laser cutting machine. - Titanium and its alloys

The beam of the fiber laser cutting machine can be well focused on the titanium metal material.The laser beam has a high thermal energy conversion rate when cutting titanium metal. When the auxiliary gas is oxygen, the chemical reaction is intense and the cutting speed is fast, but it is easy to form an oxide layer on the cutting edge. Carelessness can also cause overburning, so it is better to use air as an auxiliary gas to ensure cutting quality. For example, the laser cutting quality of titanium alloy commonly used in the aircraft industry is better. Although there will be a little sticky slag at the bottom of the cut seam, it is easy to clean. - Alloy steel

Most alloy structural steels and alloy tool steels can be cut by laser, which can ensure cutting quality and cutting accuracy. Even for some high-strength materials, as long as the process parameters are properly controlled, the cutting surface can be smooth, straight and free of slag.However, for tungsten-containing high-speed tool steel and hot mold steel, there will be erosion and slag sticking during laser cutting machine processing. - Aluminum and its alloys, copper and its alloys

Laser cutting aluminum uses the method of melting and cutting, and the auxiliary gas is mainly used to blow away the slag from the incision. For some aluminum alloys, attention should be paid to prevent the occurrence of micro-cracks between the surface of the slit. Pure copper (red copper) basically cannot be cut with CO2 laser beam due to its high reflectivity. Brass (copper alloy) uses a higher laser power, and the auxiliary gas uses air or oxygen, which can cut thinner plates.

what power of fiber laser cutter should we order?

What is the maximum thickness of the metal steel plate that the laser cutting machine can cut?

What is cutting capacity for different power of fiber laser gnerator?

Let our experts tell you!

With the popularity of laser cutter, people are required to know more about the relevant knowledge of fiber laser cutting machines. Recently, many people have come to ask about the maximum thickness of the steel plate that the laser cutting equipment can cut. In the actual working process, the cutting ability of the fiber laser cutter is related to the quality of the metal cutting machine, laser type, cutting environment, cutting speed and other factors. The use of auxiliary gas can also improve a certain cutting ability, so there is no absolute clear Cutting thickness standard. For the common metal materials in the market, the laser cutting machine can cut very well. Now I will summarize it for everyone to explain. Under certain conditions, the maximum thickness of each metal material cut by the laser cutting machine is as follows, let’s take a look.

Generally speaking, different laser cutting machines cut various metal materials according to the standard power, and the cutting limit thickness values are as follows:

1. 2000W fiber laser cutting machine, the maximum cutting thickness of carbon steel is 16mm; the maximum cutting thickness of stainless steel is 6mm; the maximum cutting thickness of aluminum plate is 4mm; the maximum cutting thickness of copper plate is 4mm;

2. 3000W fiber laser cutter, the maximum cutting thickness of carbon steel is 22mm; the maximum cutting thickness of stainless steel is 12mm; the maximum cutting thickness of aluminum plate is 8mm; the maximum cutting thickness of copper plate is 8mm;

3. 4000W fiber laser cutting equipment, the maximum cutting thickness of carbon steel is 25mm;the maximum cutting thickness of stainless steel is 12mm; the maximum cutting thickness of aluminum plate is 10mm; the maximum cutting thickness of copper plate is 10mm;

4. 6000W fiber laser cutting machine, the maximum cutting thickness of carbon steel is 25mm; the maximum cutting thickness of stainless steel is 20mm; the maximum cutting thickness of aluminum plate is 16mm; the maximum cutting thickness of copper plate is 12mm;

12000W laser cutting equipment, the maximum cutting thickness of stainless steel is 40mm, but the quality of the cutting surface above 25mm is not guaranteed, and the cutting surface below 25mm is definitely bright surface cutting. The cutting capacity of 15000W will be better, but the price is also higher.

conclude:

before order fiber laser cutter..You need check yourself what is your budget for this machine?and than we should give priority to what is thickness of your metal material? What is material propertites?is it carbon steel or stainless steel or copper brass or Aluminum? we hope this article could help you with ordering fiber laser cutting machine.

if you have any question than you can contact with us.

package and delivery for Gantry cnc plasma cutter

All of our export machinery and equipment adopt standard plywood boxes after high temperature and high pressure treatment. The boxes meet the inspection standards of the United States and the European Union; the transportation method can be transported by plane, ship, or train according to customer requirements.

We have our own long-term cooperation transportation company, which will give us more favorable prices and feasible suggestions in transportation prices, which will minimize the customer’s freight expenses, and there will never be overcharges.

We also have Gantry CNC plasma cutting machine with rotary device to cut metal tubes for option.

International Shipping Around the World

All of our cutting machines can be sent to all parts of the world by sea, air, international expFEDEX, UPS, etc. You are welcome to feedback your needs and we can provide you with the most timely and accurate freight quotation, as well as the most timely and reliable service