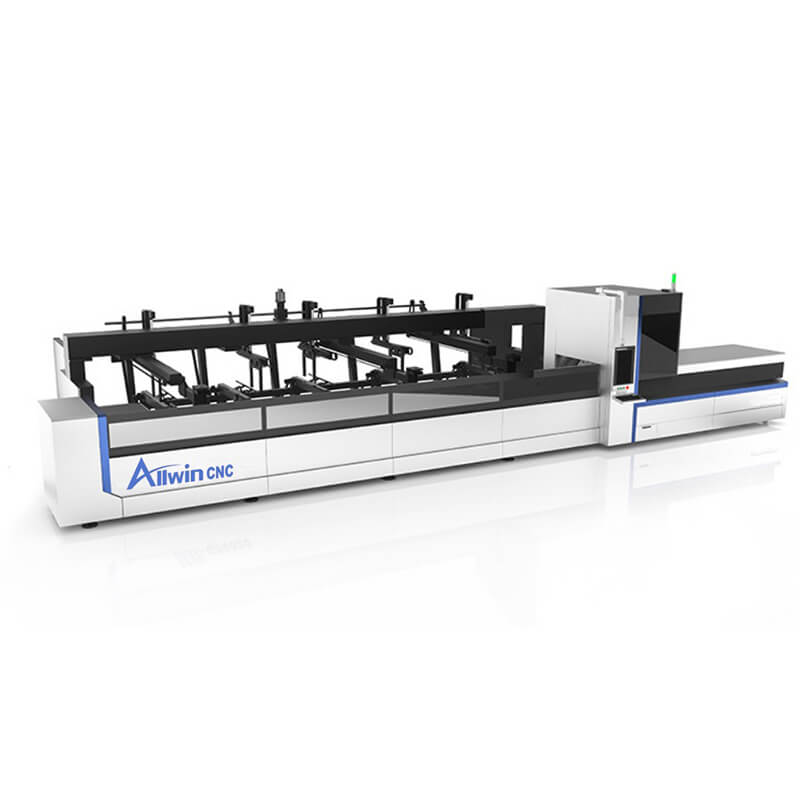

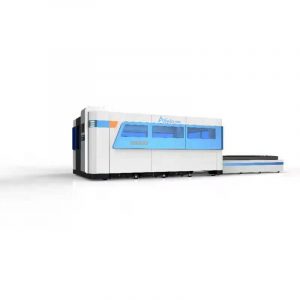

Laser Tube Cutting Machine

- Home

- Products

- fiber laser

- Laser Tube Cutting Machine

What advantage of laser tube cutting machine?Why choose laser tube cutting machine?

Tube laser cutting machine is also known as “laser tube cutting machine”

Laser tube cutting machine could cut round tube, rectangular tube, shaped tube and other profiles with high speed and high quality.

Compared with the traditional cutting process, Fiber laser cutter is flexible and does not need to build the mold, which greatly saves the development time of new products.

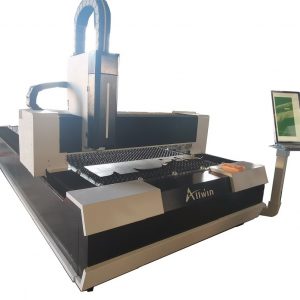

Allwin cnc Fiber laser cutting machine is specially designed for cutting metal, mainly used for cutting carbon steel, copper, stainless steel, titanium, aluminum and their alloys. CNC laser cutter can be used for plane cutting or bevel cutting, and the edges are neat and smooth. It is suitable for high-precision cutting processing such as metal plates. This metal laser cutter can meet many high-end manufacturing industries with high cutting effect and cutting accuracy. Handicrafts, tool processing, metal decoration products, advertising, small business companies, kitchenware processing and other manufacturing and processing industries.

We can design and produce laser cutting machines with different power types, among which the power types of the most popular laser cutting machines are (1000w/1500w/2000w/2500w/3000w)

ALLWIN cnc focuses on serving customers, providing customers with the most suitable products, creating value for customers, and achieving a win-win concept for all parties. We do not pursue the best, nor the lowest price, but are only responsible to customers and provide customers with satisfactory products and services.

Product Name | Metal Tube Fiber Laser Cutting Machine |

Model | 2060 /3080 |

Cutting Tube Length | 6 Meters / 8 Meters |

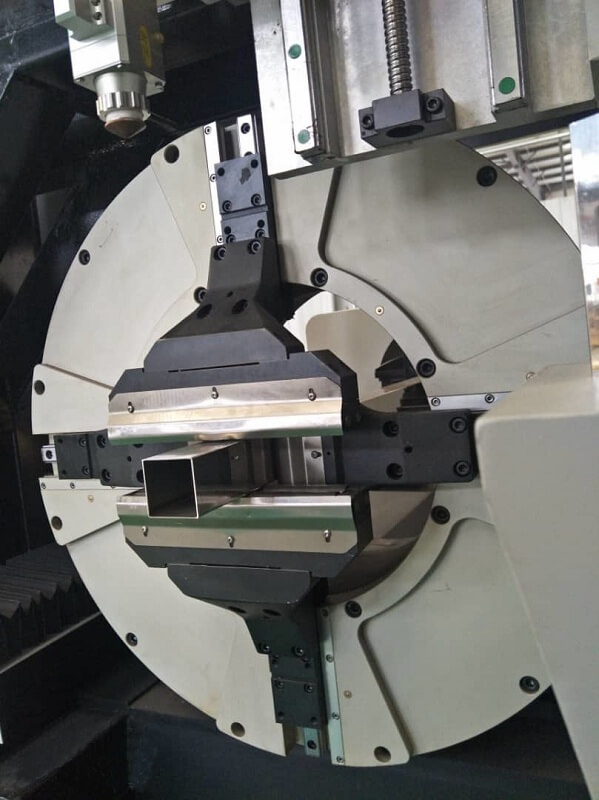

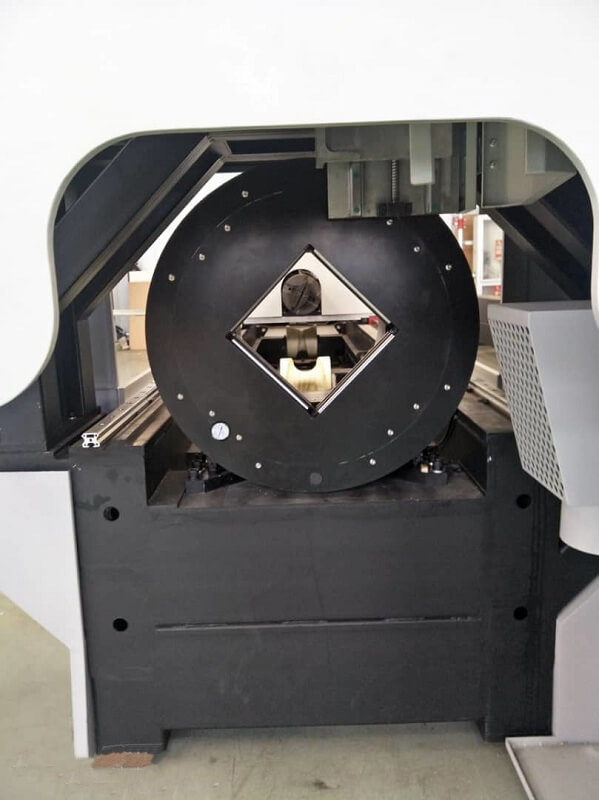

Cutting Pipe Diameter | Round pipe diameter: 100mm Square tube diagonal: 80mm |

Laser Source | World Famous Fiber Laser Source (Raycus/Max/ IPG) |

Laser Power | 1000w / 2000w / 3000w /6000W/12000W |

Transmission Method | High Precision Gear Transmission |

Table-driven system | Japanese Import Panasonic Servo Motor & Driving System |

Focus Method | Dynamic Auto-Focusing System |

Control Method | DSP Handle Offline Movement Control |

Cutting Speed | 5-60 Meters / Minute (Depending on Material and laser power) |

Carrying Capacity | 25kgs/M |

Positioning Degree | ±0.03mm |

Repeated Positioning Degree | ±0.01mm |

Large Location Speed | 75m/min |

Positionning accuracy | 0.03mm |

Power Supplied | 25kg/m |

Control software | Perfect Laser Professional Metal Laser Cutting Software |

Guarantee | 3 Years Guarantee for Fiber Laser Source 12 Month Guarantee for Laser Pipe Cutting Machine |

Training | Perfect Laser Will Offer VCD Training Video for Easy Learning Engineer Overseas Installation & Training is also Available |

1.Control pipe center deviation implement compensation reduce pipe clamping requirements,

Use famous laser head to cut different pattern according to customers’design like vertical incision method;

bevel cuts;punching;

2.How does the fiber laser cutting machine work?

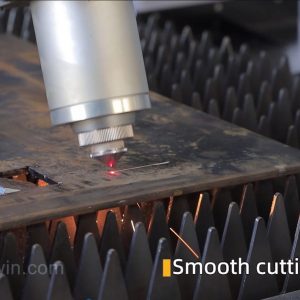

Fiber laser is a new type of laser that is newly developed in the world. This laser cnc outputs high-energy-density laser beam, which is concentrated on the surface of the workpiece, so that the area irradiated by the ultra-fine focus spot on the workpiece is instantly melted and vaporized, and the spot is moved by the numerical control mechanical system. Realize automatic cutting by irradiating position, fast speed and high precision.

Adopt four-axis chuck, automatically detect pipe shape, replace all kinds of pipe without changing chuck,

four-axis chuck could accurately control the cutting precision of pipe

Stable quality fiber laser source Max brand which has good price with very stable quality cutting works.

3D laser head WSX or Raytools laser head for professional metal tube cut works.

Applied materials

Fiber laser cutting machine is suitable for cutting all kinds of metals, and the cutting effect is better for metal materials that are not easily oxidized. In addition to cutting carbon steel, copper, stainless steel, titanium, aluminum, and their alloys have better cutting results.

Applied industries

Fiber CNC laser cutter is suitable for aerospace manufacturing, precision parts manufacturing, automobile manufacturing, ship manufacturing, subway accessories, electrical appliances manufacturing, elevator manufacturing, all kinds of machinery production, elevator manufacturing, metal craft products, advertising decoration and other small business industries.

Fiber Laser Cutter Features

1. Automatic focusing, intelligent alarm system, automatic lubrication system

2. Realize the cutting of ultra-fine holes, support three-level perforation, segmentation or progressive combination, and the proportion of small hole processing range can be reduced by about 0.3mm (the thickness of ordinary steel plate is more than 4mm)

3. Support dual-platform fast exchange system (optional), fast cutting speed.

4. Z-axis automatic tracking system, equipped with a capacitive non-contact automatic tracking system, which can automatically adjust the focus to ensure the effect of genuine cutting

5. Using the machine tool with side guide rail structure, the vertical surface bears weight vertically and is not easy to be deformed

6. Laser interferometer correction and compensation, positioning accuracy can reach micron level

7. The spot quality is good, the material deformation is small, the appearance is smooth and flat, and beautiful.

8. Adopting imported servo motor and guiding transmission mechanism, high cutting precision.

9. Use professional software to design all kinds of graphics or text at will, with flexible processing, simple and convenient operation.

10. High stability, using imported light laser (optional), stable performance, the service life of key components can reach 100,000 hours, and the laser is maintenance-free.

11. Lower maintenance cost, no laser working gas: light transmission, no need for reflective lenses, which can save a lot of maintenance costs.

12. The product is easy to operate and maintain, light transmission, no need to adjust the light path.

ALLWIN CNC Fiber Laser Cutting Machine Warranty Commitment

1. The whole fiber laser machine is 3 years, the laserer generator is 18 months, the chiller is 12 months, the lens mirror nozzle is not guaranteed.

2. Lifetime maintenance, after-sales department will provide 24/7 English online support.

3. Except for man-made damage, we are responsible for providing free accessories during the warranty period.

4. After the warranty period expires, the buyer of the fiber laser cutting machine only needs to pay the actual maintenance cost.

5. Certificate support: CE. FDA. SGS.

How Much Does A CNC Laser Cutter Cost?

The procurement cost of laser cutter consists of items::

1. Laser cutter spare parts.

2. Laser cutter software.

3. Shipping cost.

4. Customs.

A fiber laser cutter cost is from $10000.00 to 46000.00.

Package for CNC Laser Machine from ALLWIN CNC

1. Strong water resit bottom in plywood.

2. Laser source (separated plywood case) and spare parts on the laser bed.

3. Corner protect by foam and fixed by protective film.

4. All covered by strong and hard pratective film.

5. Vacuum packing.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container or frame container.

Pre-Sale Service for Fiber Laser Machine from ALLWIN CNC

1. Free Sample Cutting Service:

For free sample cutting/testing, please send us your CAD file (PLT, Al), we will do cutting in our factory and make video to show you the cutting process and result, or send samples to you to check the cutting quality.

2. Promote the upgrade and transformation of the plan:

According to customers’ product processing needs, we can design unique solutions for customers. Improve higher manufacturing efficiency and better processing quality.

3. Customized laser cutting machine customization:

According to the different application scenarios of customers, we can customize CNC laser cutting equipment that meets customer requirements, which is convenient for customers to use and improve production efficiency.

After-Sale Service for Fiber Laser cutter from ALLWIN CNC

1. As a professional fiber laser cutter manufacturer and supplier, ALLWIN CNC will supply the fiber laser machine with training video and user’s manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote, such as TeamViewer, Email, Telephone, Mobile, Whatsapp,Skype, 24/7 online chat, and so on, when you meet some problems of installation, operation or adjusting.

2. You can come to our factory for training. We will provide professional guidance, direct and effective face-to-face training. The training duration is 3 to 5 days.

3. Our engineers will conduct on-site guidance and training services in your local area. We need your help to handle visa procedures, pre-paid travel expenses, and accommodation during business trips and pre-dispatch services.