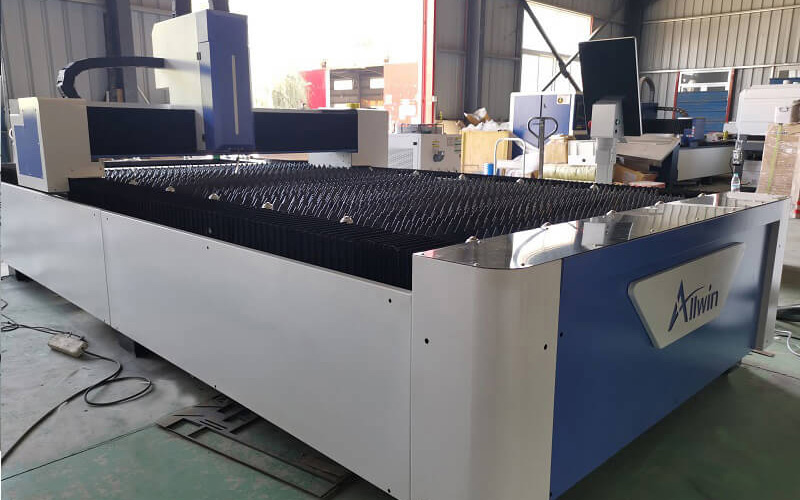

Metal Fiber Laser Cutting Machine

- Home

- Products

- fiber laser

- Metal Fiber Laser Cutting Machine

Why order metal fiber laser cutting machine

Lower consumpation of supplying electricity with very smaller noisy and saving lots of labor cost.fiber laser cutting machine could achieve smaller workpieces to cut.

compared to the traditional press machine,fiber laser cutting machine works very fast and cuts precision with saving a lots of middle processing job.end user could cut any design.

| Model: | 3015/2513/3030 |

| Category: | CNC laser cutter |

| Views: | 1800 |

| Brand: | allwin cnc |

| Rating: | 4.8 /5 based on 52 votes |

| Standard Price: | $21000.00 / Set |

| Price Range: | $10000.00 to $35000.00 / Set According to Configurations |

| Supply Ability: | 50 Sets / Month In stock! From – Jinan allwin cnc machinery co.,ltd |

| Payment Terms: | T/T,L/C |

Fiber Laser Cutting Machine Technical Parameters Model

| machine model: | ALLWIN-3015 |

| max working area | 1500mmx3000mm |

| Packing dimension | 2200mmx3700mmx1700mm |

| Laser source | 1000W/1500W/2000W/3000W/4000W RAYCUS fiber laser |

| laser head | Swiss RAYTOOLS with auto focus |

| software | Professional FSCUT2000 with Cypcut software |

| motor and driver | Japanese YASKAWA servo motors 850W |

| Reducer | Japan SHIMPO reducer |

| Water chiller | S&A brand with Dual temperature,dual control |

| Rack and pinion | Taiwan brand T-WIN rack and pinion |

| Guild rails | HIWIN GUILDER RAIL |

| Exhaust fan | Blower Exhaust fan |

| motor and driver | Japanese YASKAWA servo motors 850W |

| Air compressor | YES |

| voltage stabilizer | YES |

| Accessories included | 1 SET RAYCUS FIBER LASER SOURCE 2000W |

| 1 SET RAYTOOLS LASER HEAD(AUTOMATIC FOCUS) | |

| 1 SET WATER CHILLER | |

| CYPCUT SOFTWARE | |

| INDUSTRIAL COMPUTER | |

| FAN | |

| LASER PROTECTION GLASSES | |

| FIBER LASER CUTTING BED |

how to choose metal fiber laser cutting machine?guild to buy laser cutter.

What working size do you need?

support customize working size for laser cutting bed size according to metal material size.

regular effective working area for fiber laser cutting machine is 3000mm*1500mm/1300mm*900mm/6000mm*1500mm

What working size for plasma cutting machine depends on your metal sheet size.

so far most hot sales in the market is 1500mm*3000mm because it is more affordable and easy to ship.

What brand of fiber laser generator?

in order to achieve Revenue output maximization.

Raycus,Max or IPG brands are most welcome in china.

Fiber laser source is very core of fiber laser cutting machine.A good fiber laser source(Fiber laser generator)will effect precision cuts. its attrition rate is very lower.we realised one very serious question that lots of suppliers wants to give blood cheap price to customers to get orders..They do not care about customer at all.so that we always receive some complaints that Why my fiber laser cutter can not cut materials as same as new one i bought?it can cut 8mm thickness metal sheet when i bought 1 year ago now my machine can not cut 8mm anymore..let me tell you for sure that because of You are using bad quality fiber laser source.

To be honest,You already lost more because of working with bad quality machine.

What power of fiber laser Generator?

2000W/3000W/6000W is more popular .for middle level workshop with very competitive price compared to other manufacturer.

500W/750W fiber laser cutter with cover is best choice for gold,silver,jewellery workshop

10000W/120000W so far is a little expensive for most of middle level factories..being experienced maufacturers .we are sure that high power fiber laser cutting machine will be growing trending according to society developed with cnc equipment update ongoing. Fiber laser source is very core of Fiber laser cutting machine.

How to choose laser cutting head for laser cutting machine?

Optical parameters, compatibility, heat dissipation is mainly factor to decide how laser head works.

What is optical parameters of laser head?

Optical parameters include collimating focal length, focusing focal length, spot size, effective working focal length, adjustable focal length range, etc., these parameters are closely related to the cutting process of laser cutting head, different cutting process can be effectively realized, or laser cutting head can meet the requirements of a process

What is compatibility ?why is it so important?

work processing for Laser cutting head needs to cooperate with a variety of equipment to complete the cutting work, such as laser geneartor, water chiller,X,Y,Z on laser machine, Good compatibility of laser cutting head work synergistic ability, it will not affect the performance of other equipment

Why Heat dissipation is so important for cutting speed of fiber laser cutter?

Power of the laser cutting head determines its cutting capacity but heat dissipation will effect its duration time.

The laser heads has self-protective function.that is,overheat will stop working. Therefore, in batch production, we should pay special attention to the performance of power and heat dissipation

What brand of motion or servo motor?

Servo motor make machine moves X,Y and Z axis. A good quality servo motor could make machine moves very quiet at fast speed with very action accurately..there are lots of different brand Servo motor in the market,but We prefer Japanese Yaskawa brand because of it has very good ability to resist signal interference.

Along with china Science and technogoy is getting strong,lots of servo motors made in china are getting better and better

According to long time investigation from the market and feedback from market voice.we prefer Delta servo.whatever in running sounds or Resist singal interference or moving precision is very good than other brands made in china.

What about Quality guarantee of fiber laser cutting machine?is it reliable for after-sales service??

As everyone knows that any machine will have problem caused by different operator or something else.

being one supplier does not have service attitude or does not have service awareness please be far away from them.

no matter how good the cnc machines is..having professional techincal support is very necessary.

we need professional technical personnel to solve the problems. So, perfect after-sales is very important.

here some sincere advice from a professional manufacturer for CNC machines

Leave the suppliers who are offering very blood cheap price which far lower from the market price.

because if you choose them then it means that you are losing time and you are losing more.

You lost time and you lost order.because if you need time to send back to china to repair the parts than it is very waste time although by air transportation.it takes 1 month at least(both ways needs 2 weeks to finish import or export custom issues.

repairing time needs 2 weeks at least.overall,Your fiber laser cutting machine stop working at least 1 month.

Being professional manufacturer we would like to tell one thing that Every products has its own production cost.if your purchase order is far lower than the market it means that it is a bad quality products.especailly to Fiber laser cutting machine or CNC machines.Nobody will give you techincal support..You have to spend more time to find other engineers from other companys.

What is a fiber laser cutter?

Metal Fiber laser cutting machine is a CNC laser cutter that uses fiber laser as the light source. It has many advantages such as excellent performance, extremely high speed, and high conversion rate, which are widely used in mechanical processing and mechanical manufacturing industries. Among them, sheet metal cutting is the most typical , Cutting in the automotive field, etc.

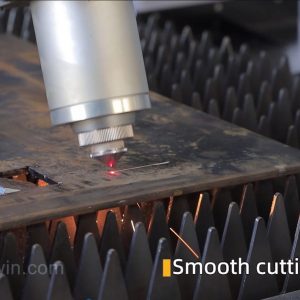

How does the fiber laser cutting machine work?

Metal fiber laser is a new type of laser that is newly developed in the world. This laser cnc outputs high-energy-density laser beam, which is concentrated on the surface of the workpiece, so that the area irradiated by the ultra-fine focus spot on the workpiece is instantly melted and vaporized, and the spot is moved by the numerical control mechanical system. Realize automatic cutting by irradiating position, fast speed and high precision.

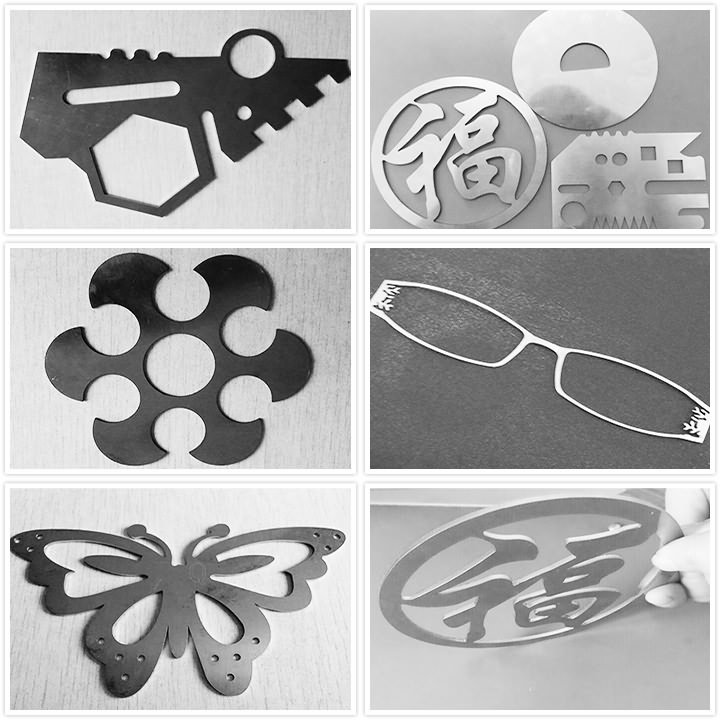

Application industries for metal Fiber laser cutting machine

Industries metal fiber laser cutting machine is suitable for cutting all kinds of metals.Stainless steel, steel,iron,brass,copper,Aluminum, aluminum alloy,titanimum,carbon steel

its cutting effect is best for metal materials compared to other metal cutting machines because of fiber laser cutting machine are not easily oxidized with very fast cutting speed

CNC fiber laser cutting machine is very popular in Aerospace manufacturing,precision indstries parts manufacturing,shipbuilding manufacturing,subway accessories,electronical appliances,elevator industries.metal fabrication and other smaller business industries,like Gold,silver, jewelry and ornaments.

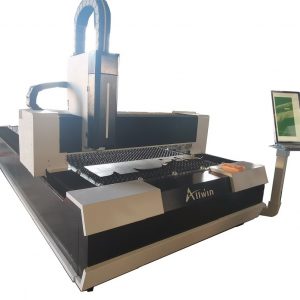

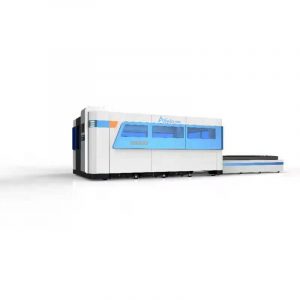

Fiber Laser Cutter Features

1. Automatic focusing, intelligent alarm system, automatic lubrication system

2. Realize the cutting of ultra-fine holes, support three-level perforation, segmentation or progressive combination, and the proportion of small hole processing range can be reduced by about 0.3mm (the thickness of ordinary steel plate is more than 4mm)

3. Support dual-platform fast exchange system (optional), fast cutting speed.

4. Z-axis automatic tracking system, equipped with a capacitive non-contact automatic tracking system, which can automatically adjust the focus to ensure the effect of genuine cutting

5. Using the machine tool with side guide rail structure, the vertical surface bears weight vertically and is not easy to be deformed

6. Laser interferometer correction and compensation, positioning accuracy can reach micron level

7. The spot quality is good, the material deformation is small, the appearance is smooth and flat, and beautiful.

8. Adopting imported servo motor and guiding transmission mechanism, high cutting precision.

9. Use professional software to design all kinds of graphics or text at will, with flexible processing, simple and convenient operation.

10. High stability, using imported light laser (optional), stable performance, the service life of key components can reach 100,000 hours, and the laser is maintenance-free.

11. Lower maintenance cost, no laser working gas: light transmission, no need for reflective lenses, which can save a lot of maintenance costs.

12. The product is easy to operate and maintain, light transmission, no need to adjust the light path.

ALLWIN CNC Fiber Laser Cutting Machine Warranty Commitment

1. The whole fiber laser machine is 3 years, the laserer generator is 18 months, the chiller is 12 months, the lens mirror nozzle is not guaranteed.

2. Lifetime maintenance, after-sales department will provide 24/7 English online support.

3. Except for man-made damage, we are responsible for providing free accessories during the warranty period.

4. After the warranty period expires, the buyer of the fiber laser cutting machine only needs to pay the actual maintenance cost.

5. Certificate support: CE. FDA. SGS.

How Much Does A CNC Laser Cutter Cost?

The procurement cost of laser cutter consists of items:

1. Laser cutter spare parts. laser nozzles,protection lens or focus lens.

2. Laser cutter software.

3. Shipping cost.

4. Customs.

A fiber laser cutter cost is from $10000.00 to 46000.00.depends on laser generator or cnc laser bed

Package for CNC Laser Machine from ALLWIN CNC

1. Strong water resit bottom in plywood.

2. Laser source (separated plywood case) and spare parts on the laser bed.

3. Corner protect by foam and fixed by protective film.

4. All covered by strong and hard pratective film.

5. Vacuum packing.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container or frame container.

Pre-Sale Service for Fiber Laser Machine from ALLWIN CNC

1. Free Sample Cutting Service:

For free sample cutting/testing, please send us your CAD file (PLT, Al), we will do cutting in our factory and make video to show you the cutting process and result, or send samples to you to check the cutting quality.

2. Promote the upgrade and transformation of the plan:

According to customers’ product processing needs, we can design unique solutions for customers. Improve higher manufacturing efficiency and better processing quality.

3. Customized laser cutting machine customization:

According to the different application scenarios of customers, we can customize CNC laser cutting equipment that meets customer requirements, which is convenient for customers to use and improve production efficiency.

After-Sale Service for Fiber Laser cutter from ALLWIN CNC

1. As a professional metal industrial fiber laser cutter manufacturer and supplier, ALLWIN CNC will supply the fiber laser machine with training video and user’s manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote, such as TeamViewer, Email, Telephone, Mobile, Whatsapp,Skype, 24/7 online chat, and so on, when you meet some problems of installation, operation or adjusting.

2. You can come to our factory for training. We will provide professional guidance, direct and effective face-to-face training. The training duration is 3 to 5 days.

3. Our engineers will conduct on-site guidance and training services in your local area. We need your help to handle visa procedures, pre-paid travel expenses, and accommodation during business trips and pre-dispatch services.