professional manufacturer for metal fiber laser cutting machine we sum-up some frequence problem from our clients:

Abnormal capacitance alarm from height controller(THC)

fiber laser cutter use capacitance height controller(THC) to control cutting height between nozzles tip and metal sheet.

Generally speaking:Cut height is 0.6mm-1.1mm piercing height:3.5mm-4mm

if too small cut height will make laser head hit against metal sheet.

if too big cut height will redeuce gas concentration or pressure

Piercing height could be 3.5mm-4mm will stop slags damage focus lens.

super senstive response THC is very important to avoid laser head hit against metal sheet.

How to make THC have senstive response?—timely calibration to be sure Excellent Servo calibration&Excellent Capacitance.

When to Re-calibrate THC?changed new nozzles or changed any component of laser head

Especially changed different thickness metal sheet then need Re-calibrate THC

Sometimes failed on calibration.Here we guild you to find reason why failed on calibration THC

(1) check Ceramic ring is loose or broken?(2) Check Nozzles loose or broken?(3)RF cable(Signal cable) is broken?

(4)contact point is broken between ceramic and nozzles?

why at same plate its half cutting quality is clean another half is bad?

QBH is loose or cutting nozzles is loose or Ceramic ring is loose.

why cutting quality is bad?

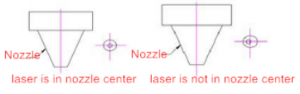

(1)checking cutting parameter from software is correct? especially cut focus,cutting speed and gas pressure.

(2) Checking protective lens or focus lens?especially to lower protective lens.

(3)checking the focus is concentrated on one dot (use dot way to adjust)

(4)checking gas pressure is enough or cleanning of gas.

Why life of protective mirror is so short?

Laser protection lens is designed to protect the focusing lens. To save the cost of laser equipment during the processig cuts.

General speaking:For Buttom mirror is 70 hours.

for new operator , maybe needs to be changed more often..its life is 30 hours.

for skilled operator..its life will be 70 hours.

Check the buttom protective mirror is clean or not before starting cutting every day.

If dirty, get it clean using Non woven alcohol cotton swab.

Keep it clean, then longer life time.

General speaking:For Top mirror is 7 months.

if top mirror is broken very easier than you must find reason why?

first of all,Dismount QBH between QBH of laser source connect with QBH of laser head.

check Lens of QBH on fiber laser..most posibility is QBH on fiber laser is burnt or dirty.

lots of clients are confused about why lens of QBH on fiber laser is broken?because of use wrong way to mount so that dust enter into.

Here we remind everyone that

please check this link to teach you how to mount QBH.

let us look back now. Having clean workshop is very important for fiber laser cutting machine.

Timely clean laser head is very necessary and change water for water cooler.

if you have any problem then pls contact with us.