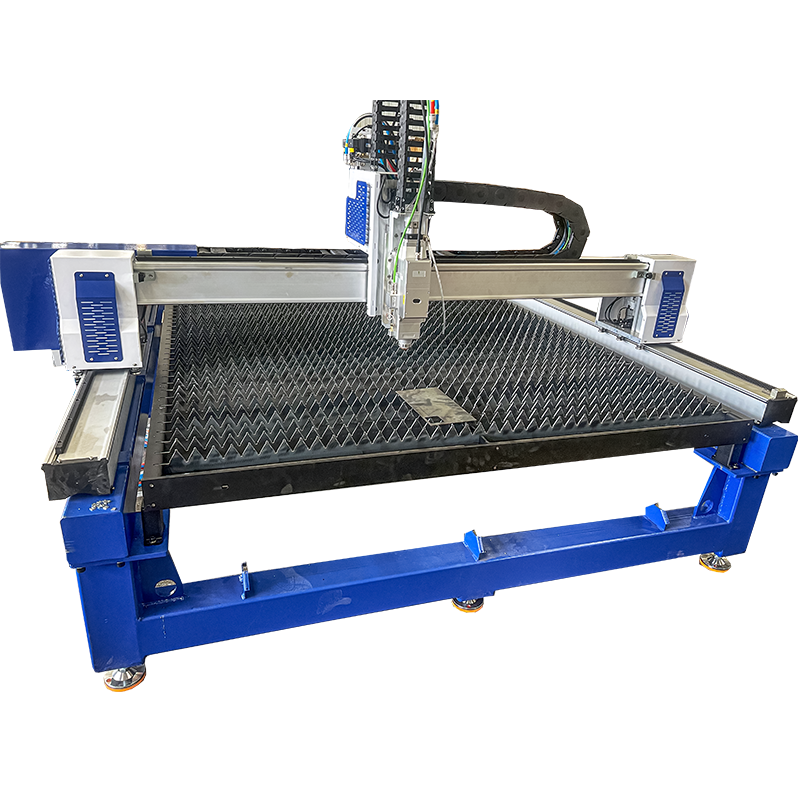

Detachable Laser Cutting Machine Features

Detachable cutting table design minimizes shipping volume and logistics cost.

Same high‑performance motors, laser source and CNC system as standard models.

Precision milled frame and flat table bed ensure stable performance and high accuracy.

Compact packaging size yet full working area (e.g., 1500 × 3000 mm) for metal sheet processing.

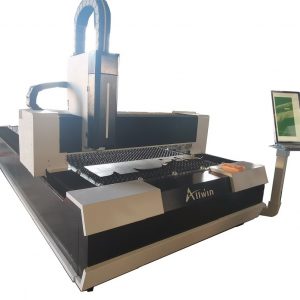

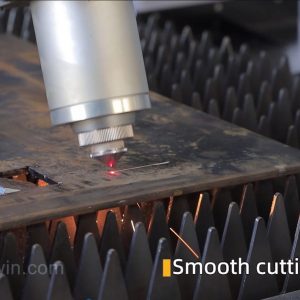

Compatible with top laser heads (e.g., Raytools) and premium fiber laser sources for excellent cutting.

| Model: | 3015/2513/3030 |

| Category: | Portable laser cutting machine |

| Views: | 1800 |

| Brand: | Fwin cnc |

| Rating: | 4.8 /5 based on 52 votes |

| Standard Price: | $6800.00 / Set |

| Price Range: | $7000.00 to $11000.00 / Set According to Configurations |

| Supply Ability: | 50 Sets / Month In stock! From – Jinan allwin cnc machinery co.,ltd |

| Payment Terms: | T/T,L/C |

Fiber Laser Cutting Machine Technical Parameters Model

| 1 | Max working area | 1500mmx3000mm | |||

| 2 | Packing size | L*W*H 3850mm*720mm*360mm 620KGS | |||

| L*W*H 2400mm*1210mm*1020mm 500KGS | |||||

| 3 | Laser source | MAX BRAND 3.0KW | |||

| 4 | Laser head | Swiss Raytools 110 with auto focus | |||

| 5 | Software | Professional raytools software | |||

| 6 | Motor and driver | China brand servo and driver | |||

| 6 | Positioning accuracy along the X, Y, and Z axes | ±0.03mm | |||

| 7 | The temperature mode of operation | 0℃~40℃ | |||

| 8 | Proportional valve for automatic gas control | Taiwan SMC Proportional valve | |||

| 8 | Electrical components | Top chinese brand Chint | |||

| 9 | Water chiller | HANLI brand with Dual temperature,dual control | |||

| 10 | Working voltage for 3.0kw | 3phrase 380V with 50hz | |||

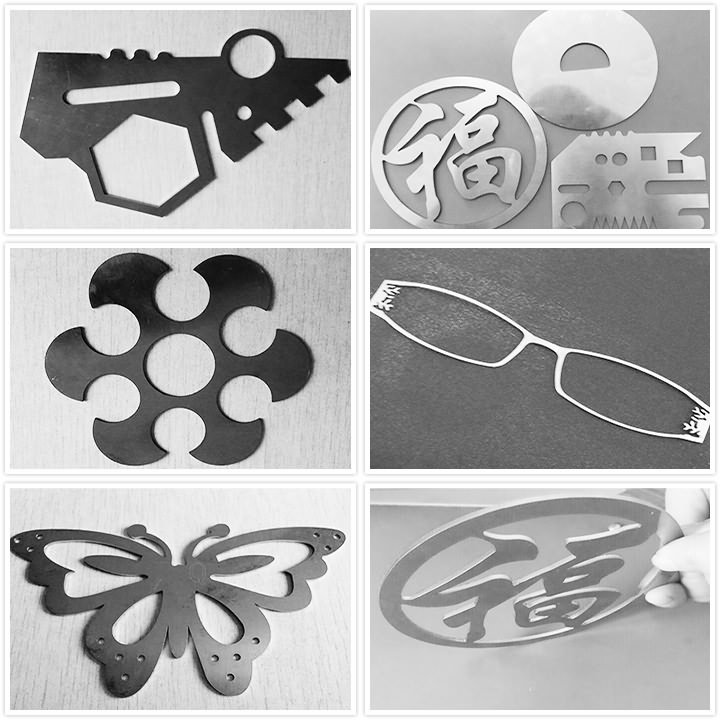

| 11 | cutting capacity with 3000W | 18mm thickness for carbon steel | |||

| cutting capacity with 3000W | 8mm thickness for stainless steel | ||||

| 12 | Attached parts with machine | 10pcs nozzles+2pc ceramic holder+15pcs protective lens | |||

Why Choose This Detachable Laser Cutting Machine

Choosing a detachable laser cutting machine offers several advantages:

For buyers seeking international shipping and export logistics, the detachable design reduces freight costs and handling complexity. FwinCNC

You gain the same cutting precision and speed as full‑sized industrial machines, but with more flexibility and lower packaging cost.

Ideal for small to medium enterprises or global buyers who need a cost‑efficient metal sheet laser cutter without sacrificing performance.

The compact design empowers on‑site installation, easy integration into workshops or new production lines.

By selecting this model, users get both flexibility (detachable/portable) and industrial grade cutting performance, making it a smart investment for growing operations.

Application industries for metal Fiber laser cutting machine

This detachable laser cutting machine is well‑suited for a wide range of metal processing tasks:

Metal Fabrication Workshops – Cutting stainless steel, carbon steel, and aluminum sheets with high precision and speed.

Construction & Structural Engineering – Processing frames, beams, custom metal parts either in the factory or on‑site.

Automotive & Aerospace Components – Precision cutting of lightweight metals and complex shapes where accuracy and consistency matter.

Household Appliance Manufacturing – Ideal for kitchenware, appliance parts, stainless steel panels where cost and space efficiency are essential.

Export‑oriented SMEs – Firms shipping machines globally benefit from lower packing size and freight cost while keeping full cutting capability.

ALLWIN CNC Fiber Laser Cutting Machine Warranty Commitment

1. The whole fiber laser machine is 3 years, the laserer generator is 18 months, the chiller is 12 months, the lens mirror nozzle is not guaranteed.

2. Lifetime maintenance, after-sales department will provide 24/7 English online support.

3. Except for man-made damage, we are responsible for providing free accessories during the warranty period.

4. After the warranty period expires, the buyer of the fiber laser cutting machine only needs to pay the actual maintenance cost.

5. Certificate support: CE. FDA. SGS.

How Much Does A CNC Laser Cutter Cost?

The procurement cost of laser cutter consists of items:

1. Laser cutter spare parts. laser nozzles,protection lens or focus lens.

2. Laser cutter software.

3. Shipping cost.

4. Customs.

A fiber laser cutter cost is from $10000.00 to 46000.00.depends on laser generator or cnc laser bed

Package for CNC Laser Machine from ALLWIN CNC

1. Strong water resit bottom in plywood.

2. Laser source (separated plywood case) and spare parts on the laser bed.

3. Corner protect by foam and fixed by protective film.

4. All covered by strong and hard pratective film.

5. Vacuum packing.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container or frame container.

Pre-Sale Service for Fiber Laser Machine from ALLWIN CNC

1. Free Sample Cutting Service:

For free sample cutting/testing, please send us your CAD file (PLT, Al), we will do cutting in our factory and make video to show you the cutting process and result, or send samples to you to check the cutting quality.

2. Promote the upgrade and transformation of the plan:

According to customers’ product processing needs, we can design unique solutions for customers. Improve higher manufacturing efficiency and better processing quality.

3. Customized laser cutting machine customization:

According to the different application scenarios of customers, we can customize CNC laser cutting equipment that meets customer requirements, which is convenient for customers to use and improve production efficiency.

After-Sale Service for Fiber Laser cutter from ALLWIN CNC

1. As a professional metal industrial fiber laser cutter manufacturer and supplier, ALLWIN CNC will supply the fiber laser machine with training video and user’s manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote, such as TeamViewer, Email, Telephone, Mobile, Whatsapp,Skype, 24/7 online chat, and so on, when you meet some problems of installation, operation or adjusting.

2. You can come to our factory for training. We will provide professional guidance, direct and effective face-to-face training. The training duration is 3 to 5 days.

3. Our engineers will conduct on-site guidance and training services in your local area. We need your help to handle visa procedures, pre-paid travel expenses, and accommodation during business trips and pre-dispatch services.