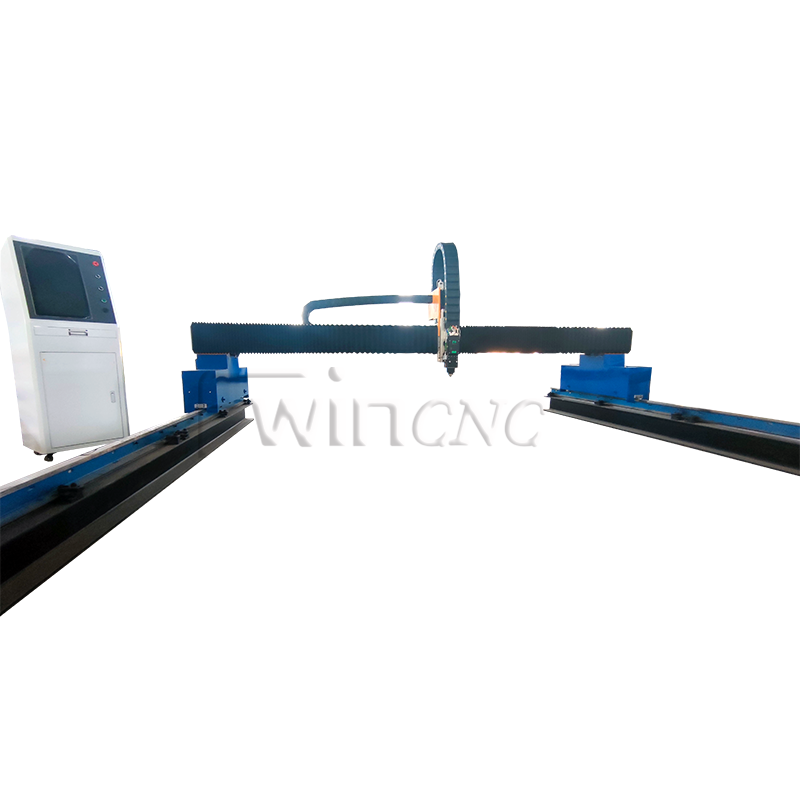

Heavy Gantry Laser Cutting Machine

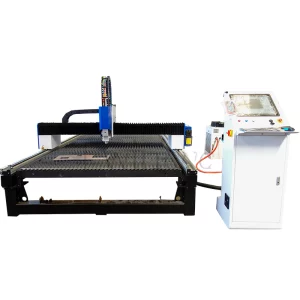

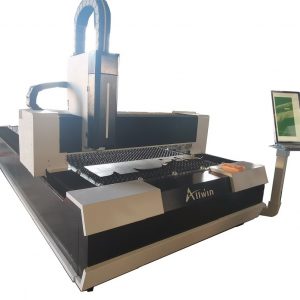

The square and round pipe laser cutting machine is designed for precision cutting of round, square, and rectangular tubes with high speed and clean edges. Its flexible configuration and stable structure make it ideal for metal fabrication industries. Easy to operate and reliable, built for long-term productivity in diverse production environments.

Features

Massive gantry frame with deep welded bed for outstanding rigidity and minimal deformation.

High-power fiber laser source (typically 12 kW / 20 kW / 30 kW) to cut thick steel plates with ease.

Precision linear motors or servo drives on both X and Y axes for high speed and accuracy.

Large working area (e.g., 6 m width or more) to handle oversize sheets in one pass.

Advanced CNC control system with material database, automatic parameter matching and job management.

Heavy-duty exchange table or automatic sheet loader for high production efficiency.

Integrated safety enclosure and fume extraction system for industrial compliance.

Heavy Gantry Laser Cutting Machine Technical Parameters

| 1 | Max working area | 2500mmx6000mm | |||

| 2 | Packing size | 3850mmx580mmx1100mm&1800.00kgs | |||

| 3 | Laser source | MAX BRAND 6.0KW | |||

| 4 | Laser head | Swiss RAYTOOLS BK06 with auto focus | |||

| 5 | Software | Professional raytools software XC3000S | |||

| 6 | Motor and driver | HCFA Servo motor and driver | |||

| 7 | Y AXIS | 2*1300W HCFA servo motor | |||

| 8 | X AXIS | 1*850W HCFA Servo motor | |||

| 9 | Z axis | 1*400w HCFA Servo motor | |||

| 10 | Water chiller | S&A brand with Dual temperature,dual control | |||

| 11 | Working voltage for 6.0kw | 3phrase 380V with 50hz | |||

| 12 | Attached parts with machine | 25pcs nozzles+2pc ceramic holder+10pcs of protective mirror | |||

Why Choose This Heavy Gantry Laser Cutting Machine

Opting for a heavy gantry laser cutter offers significant advantages:

When your production involves oversized plates or heavy steel processing, the large-format frame ensures one-pass cutting, reducing welding or assembly costs.

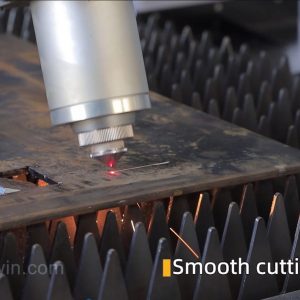

High-power fiber laser means smoother cuts, reduced secondary processing, and greater thickness capacity.

The rigid structural design ensures long-term accuracy and minimal maintenance downtime, ideal for demanding industrial environments.

Centralised control system and automation options lower labor costs and increase throughput, delivering a faster return on investment.

For companies scaling up or entering high-volume steel fabrication (construction, shipbuilding, heavy machinery), this machine becomes a strategic asset rather than just equipment.

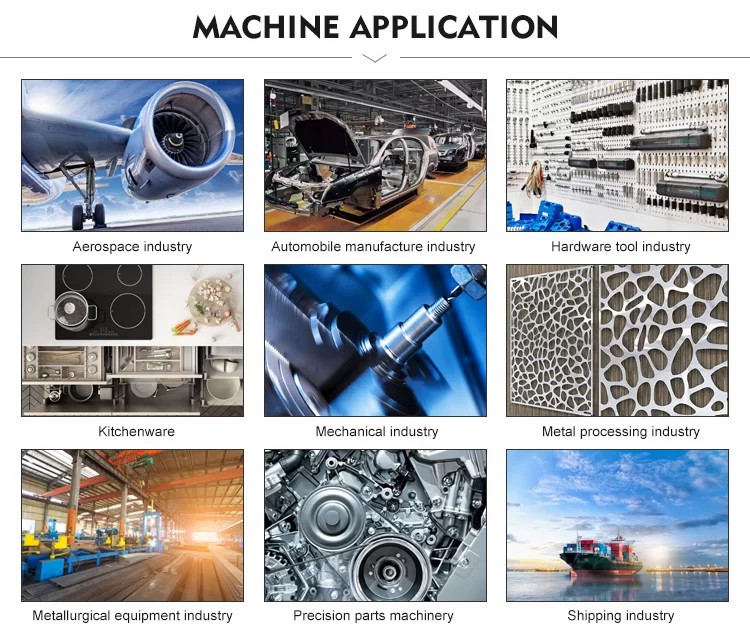

Application industries for Heavy Gantry Laser Cutting Machine

Construction & structural fabrication — Cutting large steel plates for beams, columns, trusses, platforms.

Heavy machinery & equipment manufacturing — Processing large structural components, chassis, heavy frames.

Shipbuilding and offshore fabrication — Oversize plate cutting for hulls, decks, bulkheads.

Automotive & truck manufacturing — Cutting large floor pans, frames, body structures from thick sheets.

Industrial warehousing and power supply industry — Metal enclosures, cabinets, large-format panels and structural modules.

ALLWIN CNC Fiber Laser Cutting Machine Warranty Commitment

1. The whole fiber laser machine is 3 years, the laserer generator is 18 months, the chiller is 12 months, the lens mirror nozzle is not guaranteed.

2. Lifetime maintenance, after-sales department will provide 24/7 English online support.

3. Except for man-made damage, we are responsible for providing free accessories during the warranty period.

4. After the warranty period expires, the buyer of the fiber laser cutting machine only needs to pay the actual maintenance cost.

5. Certificate support: CE. FDA. SGS.

How Much Does A CNC Laser Cutter Cost?

The procurement cost of laser cutter consists of items:

1. Laser cutter spare parts. laser nozzles,protection lens or focus lens.

2. Laser cutter software.

3. Shipping cost.

4. Customs.

A fiber laser cutter cost is from $10000.00 to 46000.00.depends on laser generator or cnc laser bed

Package for CNC Laser Machine from ALLWIN CNC

1. Strong water resit bottom in plywood.

2. Laser source (separated plywood case) and spare parts on the laser bed.

3. Corner protect by foam and fixed by protective film.

4. All covered by strong and hard pratective film.

5. Vacuum packing.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container or frame container.

Pre-Sale Service for Fiber Laser Machine from ALLWIN CNC

1. Free Sample Cutting Service:

For free sample cutting/testing, please send us your CAD file (PLT, Al), we will do cutting in our factory and make video to show you the cutting process and result, or send samples to you to check the cutting quality.

2. Promote the upgrade and transformation of the plan:

According to customers’ product processing needs, we can design unique solutions for customers. Improve higher manufacturing efficiency and better processing quality.

3. Customized laser cutting machine customization:

According to the different application scenarios of customers, we can customize CNC laser cutting equipment that meets customer requirements, which is convenient for customers to use and improve production efficiency.

After-Sale Service for Fiber Laser cutter from ALLWIN CNC

1. As a professional metal industrial fiber laser cutter manufacturer and supplier, ALLWIN CNC will supply the fiber laser machine with training video and user’s manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote, such as TeamViewer, Email, Telephone, Mobile, Whatsapp,Skype, 24/7 online chat, and so on, when you meet some problems of installation, operation or adjusting.

2. You can come to our factory for training. We will provide professional guidance, direct and effective face-to-face training. The training duration is 3 to 5 days.

3. Our engineers will conduct on-site guidance and training services in your local area. We need your help to handle visa procedures, pre-paid travel expenses, and accommodation during business trips and pre-dispatch services.