Why No Pilot Arc Or No Cutting Arc Starting In CNC Plasma Cutting Machine?

How chek our CNC plasma cutting machine when No Pilot Arc or No cutting Arc?Why no pilot arc?

it has two different condition

No cutting arc starting?or Having arc starting but can not keep on.

if your plasma does not have ARC STARTING than check 7 following solutions

1) Checking out Ground electrode

Make sure metal clamp connect with metal sheet.

bad contacts of ground cable may occur

things to do:

use specicial ground tools and be sure no insulation on surface of the workpieces. don’t use aged ground cable.

2) Checking out pressure for compressed air

Must be sure giving same air pressure as plasma source request..Normally speaking,Plasma source needs 0.45-0.7Mpa.

Most of plasma generator has indicator lamp or pilot light for showing air pressure.

if Your plasma source is water cooled than check “water Pressure”Light on or off.

if air pressure is far higher. the air flow will blow away concentrated arc column so that weaken its cutting ability.

if air pressure is far lower.then optimal plasma arcing can not formed.This will result in a poor quality cut and build up slag.

Things to check:

is the compressor providing enough air? are the air channels blocked?is the air filter relief valve set correctly?

3)Check Nozzles or electrodes broken or Improper installation

if cutting torch is water cooled style than you need switch on water cooler to keep on water-cycle before start arc.

4)check cutting torch and cable.

Especially to cuting torch..it is very easy to block torch after use sometimes. the garbage or trash jam could block its air flow.

5)Check voltage supply

Use AC multimeter to measure voltage supplying if it is 03 Phrase AC380V. if it is lack of phrase.

there should be large-scale electrical facilities at the use site of the CNC plasma cutting machine.

the failure of the internal main circuit components of the cutting machine will cause the input AC voltage to be low and cause the ARC to break.

most of users coud realise check above 5 points at first.

However it still no Arcing after check above 5 points…than You need check followling steps.

6)check plasma source itsself.

How to check plasma source itself?

Cut off “ControL singal”interface and use “Short-connected”way to Start up plasma generator.

If poilot Arc or cutting arc come out on Torch than means Plasma generator and cutting torch works fine.

Because of our machine are CNC.THC(Automatic height control system with Plasma source working together)

Here we would like to share one Secret about CNC

Finally.All 6 points above we mentioned are fine..However,still not having Pilot Arc or cutting arc comming out.

Now we need check its “Arc Signal”

7)Checking out Arc signal cable

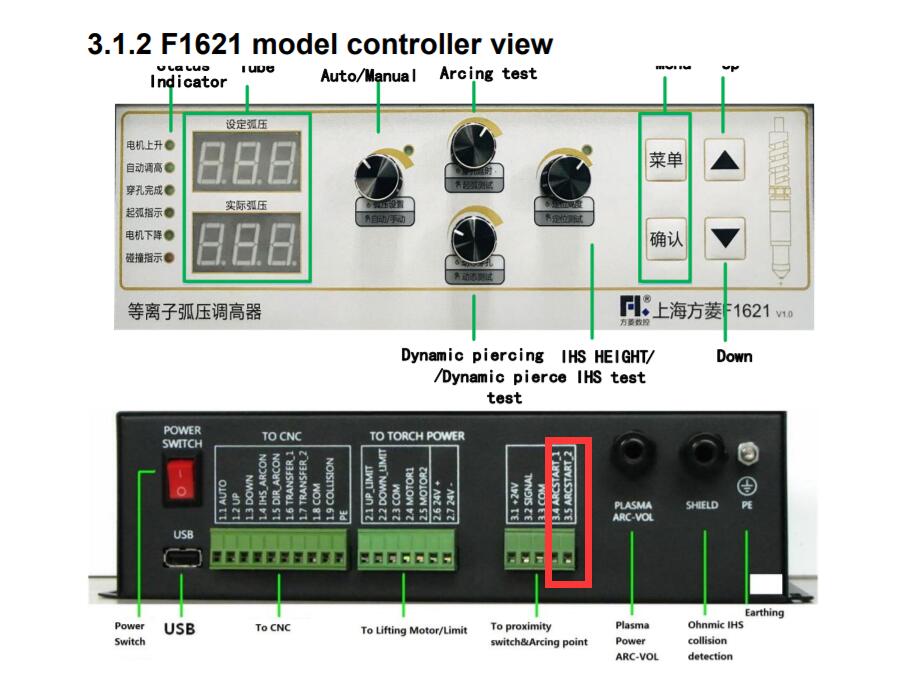

Which cable is singal cable?how to find singal cable? let us take Height controller FANGLING F1621 as example.

ACR START-1 & ARC START-2

take off cover to check the cable is broken or fine with multi-meter.

singal Arcing point on Height controller(THC)

connect with Ground clamp to metal sheet.

Why No Continuous Pilot Arc Or Why No Cutting Arc?

We always receive feedback from customers why pilot arc start for 3 seconds than stop ?why can not keep on cutting Arc?

why cutting Arc breaking off suddenly?

It is a quite normal or very common problem.However, it is hard to say why caused it?

most of clients firstly realise check Nozzles,electrodes,cutting torch or Supplying voltage or air pressure.

They dont know how to do after checking Nozzles,cutting torch or voltage and air pressure.

let us guild you how to solve step by step.

1. check “actual ARC Voltage”on THC(Height controller).

If “Actual voltage”keep showing 0 during pilot Arc starting the moment or still shows other numbers?

if Shows 0 means signal between Plasma source and Height controller has problem.

PLASMA POWER ARC VOLTAGE can not give signal to THC(height controller)

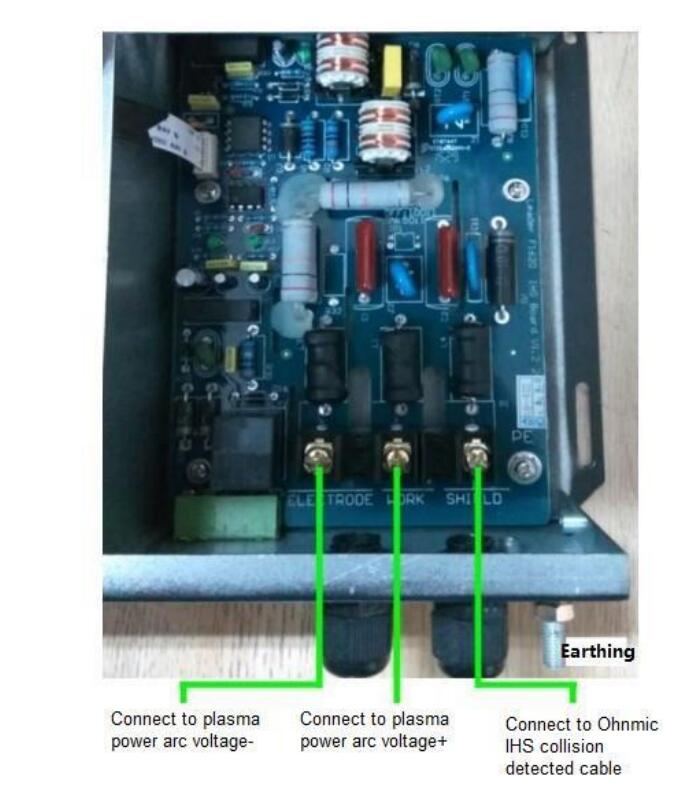

Kindly note:POSITIVE of ARC VOLTAGE on plasma power should connect with ELECTRODES pole on THC.

NEGATIVE OF ARC VOLTAGE on Plasma power should connect with WORK pole on THC

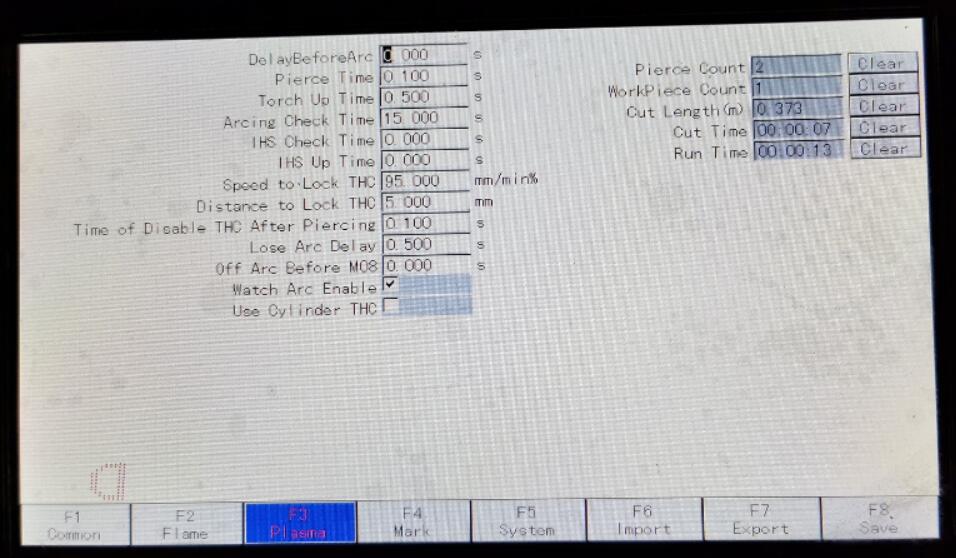

2.Check Parameter of Control system

If “Actual ARC voltage“shows number like 120 OR 150 not 0 than check paramter of control system.

especially to ARC checking time or pierce time. if too short time than it will not piercing compeletely.

how to connect between Arc voltage on plasma power and

THC(Height controller)

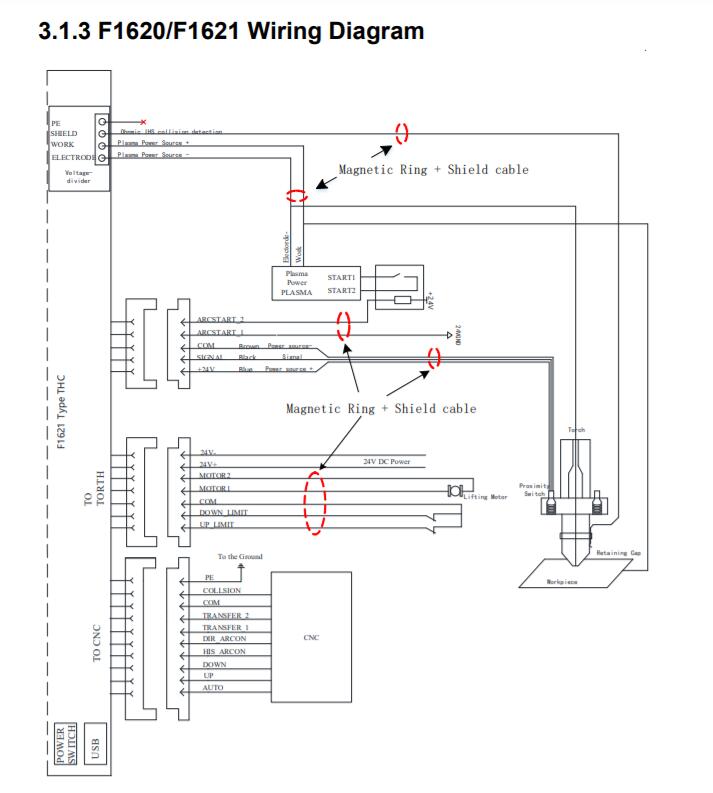

Wiring diagram for THC in plasma cutting machine

take fangling 1621 THC as example..Check its plasma parameter Pierce time Arcing checking time

In additional to the above objective reasons.Why the Pilot Arc or cutting Arc breaking off in plasma has something to do with the user.

if the users are not familiar with the equipment Than it causes the ARC to be broken.

Hence.end user should read manual book very well for cnc plasma cutting machine before starting opration.

If you have any more confused question please contact us free.