In most metal fabrication applications involving laser welding machine/laser cleaning machine for rust

the operator is only involved in entering commands to the welding machine.

But for some small workshop products, manual  production is still the first choice.

production is still the first choice.

The handheld laser welding machine is a welding machine designed for the processing of small products.

This article will provide a detailed introduction to Laser welding machine and recommend suitable products.

1. What is Laser Welding Used For?

The handheld laser welding system is easy to operate, fast welding, and requires no consumables.

These features make it suitable for small machining welding.

The application of this product(fiber laser welding and laser cleaning machine)is concentrated in complex and irregular welding process applications,

such as kitchen utensils, chassis, sheet metal, stainless steel doors, etc. Small parts commonly include stainless steel faucets, door handles, door locks, these products are suitable for hand-held lasers Welding machines are processed and have relatively low welding costs.

According to different demands.We have more option power for your choice

i.e 1000W/1500W/2000W Continuous laser generator or impulse style laser generator 200W/300w/500w.

In recent years, it has replaced conventional TIG and electric welding as the mainstream in these applications.

2. What’s the different between laser welding and tig welding

TIG welding has been a production process since the 1940s, while lasers only began to be used on a large scale in the 1980s.

Laser welding has the following advantages:

High consistency of welding quality

Laser welding process has the highest laser precision and is ideal for welding complex shapes to create clean, strong welds.

Small heating area

Laser welding has a small heating area, and the welding area is not deformed, which can keep the appearance clean.

high productivity

The welding speed of laser welding is very high, which helps to increase production efficiency.

fast cooling

The material can be processed immediately after laser welding, compared to the much slower cooling rate of TIG welding.

This feature also increases the efficiency of production. However, be aware that this feature may cause some metals to crack.

Welds are very small

Laser welding does not require post-weld processing such as grinding or trimming. The weld surface is smooth and can even be painted directly.

Easy access to difficult areas

The laser beam is a thin, straight line, so it can easily work through gaps in structures, and welding areas under heavy obstacles. In contrast, electrodes have difficulty reaching these areas.

3. How does Laser Welding Work?

The laser can focus the high-energy beam of energy amplification on the welding seam, melting the welding point in a short time.

The two surfaces of the seam will blend together in seconds.

In the field of laser welding, there are three common types of lasers: gas lasers, solid-state lasers, and fiber lasers

Gas laser

Gas lasers use a variety of gases to generate laser light, such as helium and carbon dioxide. Such gas mixtures require the use of a low-current, high-voltage power source to “excite” the radiation, producing a beam of light. Gas lasers are most commonly used for keyhole welding of car bodies.

Solid-State Lasers

Solid state lasers are lasers that use solid laser materials as the working substance. The working medium is uniformly doped with a small amount of activated ions in the crystal or glass as the matrix material. Typically used for welding, punching, and cutting involving glass materials.

Fiber Lasers

Fiber lasers are the most versatile and can be used for welding both thin and thick materials. Compared to other laser types, they are low cost, but the quality of the welds is high.

The laser welding machine supports a variety of methods, including spot welding/butt welding/lap welding/sealing welding/seam welding. Each welding method is suitable for different applications. One of the great advantages of laser welding is that it can act on a wide variety of materials. Such as carbon steel, aluminum, stainless steel, titanium, plastic, etc. Regardless of the thickness of the thin Haihui Temple, laser welding can perform relatively firm welding. This is a feature that TIG welding does not have. For thin metals, TIG welding tends to deform the material.

Cost gap

The initial investment of laser welding equipment is much higher than that of TIG welding. However, for large manufacturers, the increased cost of purchasing equipment is often covered by more efficient production efficiency within a certain period, so as to achieve cost recovery. In addition, laser welding has almost no consumables. Compared with TIG welding, there is no need to consider the cost of consumables and the loss caused by downtime when using it for a long time. However, it should be noted that the maintenance cost of laser welding equipment is much higher than the cost of TIG welding equipment, so in terms of overall cost, laser welding is still higher than TIG welding. Which one to choose depends on many factors such as production scale, specific application, and budget.

4. What are the benefits of the ALLWIN Laser Welding Machine

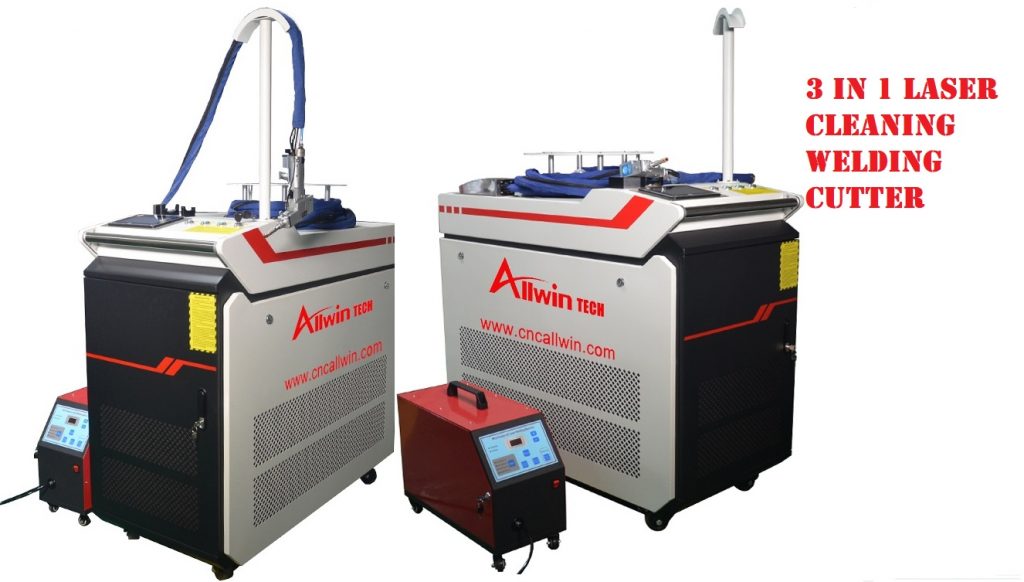

We recommend you to use a reliable laser welding machine to ensure the quality and efficiency of your production. Allwin offers the handheld Laser Welding Machine to meet your production needs. Its biggest feature is that it is extremely portable, and its size is only comparable to a refrigerator.

Moreover, compared with using TIG welding, laser welding is less difficult to get started, and employees can start production work with simple training. In addition to that, it was mentioned earlier that laser welding is very suitable for processing complex surfaces and it cools quickly.

This is very suitable for small factories to process parts, and also meets the production needs of such users.

This portable laser welding machine from All win is equipped with a fiber laser.

The laser components use well-known brands Raycus/JPT/Max. and German IPG. The photoelectric conversion rate is greatly improved, the laser power is strong, and the welding seam is small. In addition, this equipment is equipped with an independent chiller, which can quickly cool the fiber laser with a compressor, which is very convenient. For this device, All win can be 1000W, 1500W, and 2000W three kinds of high-power laser for you to choose. The matching automatic wire feeding device can improve the welding quality.

The price of this laser welding machine is very competitive.

You can contact our sales for preferential prices. All equipment supports shipping to the destination by sea. When in stock, we ship within three days. Feel free to get a quote!