Round Pipe Cutting Machine for Precision CNC Plasma Tube Processing

- Home

- Products

- CNC Plasma Cutter

- Round Pipe Cutting Machine for Precision CNC Plasma Tube Processing

High-Performance Round Pipe Cutting Machine for Precision CNC Plasma Tube Processing

The Round Pipe Cutting Machine is a CNC plasma tube cutting system engineered for precise processing of cylindrical metal pipes. Designed for structural steel fabrication and industrial manufacturing, this machine ensures accurate contour cutting, smooth edge quality, and reliable automation. It supports various pipe diameters and thicknesses, delivering efficient performance for both batch production and customized metal projects. With stable operation and intelligent CNC control, it improves productivity while reducing manual labor and material waste.

| No. | function | For light weight pipe | ||

| 1 | metal pipe | Round pipe diameter 50mm-219mm | ||

| 2 | Pipe length | 6000mm | ||

| 3 | Cutting Mode | Plasma | ||

| 4 | Rotary attachment | chuck diameter 200mm-1pcs | ||

| 5 | Driving and motor | stepper motor | ||

| 6 | loading capacity | 240kgs | ||

| 7 | lifting method | manual | ||

| 8 | Controller system | one set of startfire | ||

| 9 | Height controller | startfire | ||

| 10 | rotation speed | 0.1-25r/min | ||

| 11 | position accuracy | ±0.1mm | ||

| 12 | cutting speed | 100~6000mm/min | ||

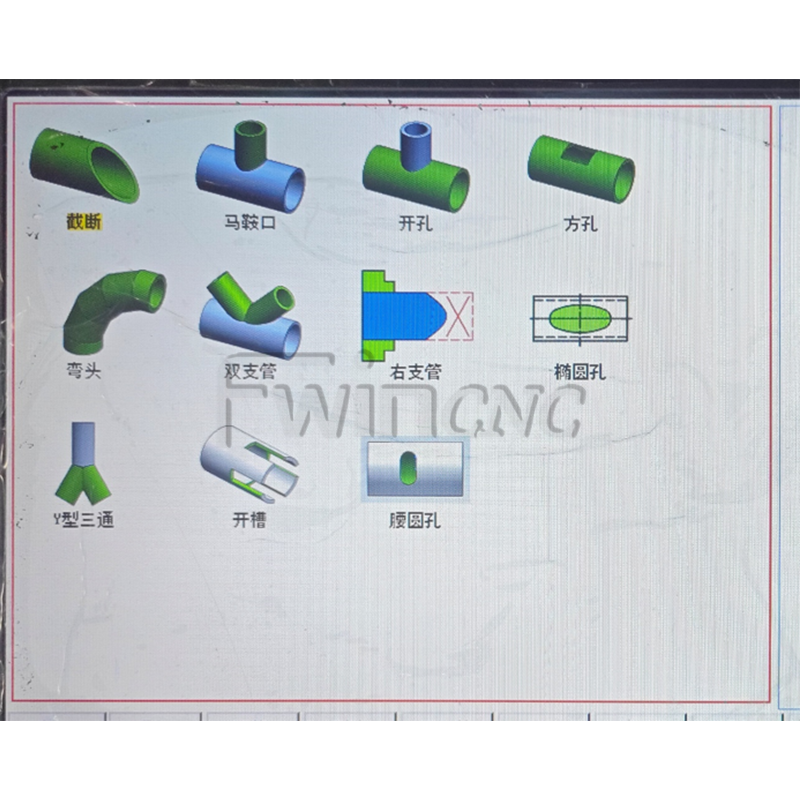

| 13 | Attached design | 11 cutting patterns | ||

| 14 | input power | 220±10%V AC50HZ/60HZ | ||

| 15 | cutting design | photo showing | ||

| 16 | tramsmission method | USB | ||

| Software | for option | |||

| 18 | Electrical components | CHINT | ||

Round Pipe Cutting Machine – Advanced CNC Plasma Pipe Cutting System

The Round Pipe Cutting Machine is a professional CNC plasma pipe cutting solution developed for accurate and efficient processing of cylindrical metal tubes. Designed for industrial metal fabrication, this CNC pipe cutter delivers clean profiles, precise intersections, and consistent cutting quality across a wide range of pipe diameters. It is widely used in structural engineering, construction projects, and customized metal manufacturing.

Precision CNC Plasma Technology for Metal Pipe Cutting

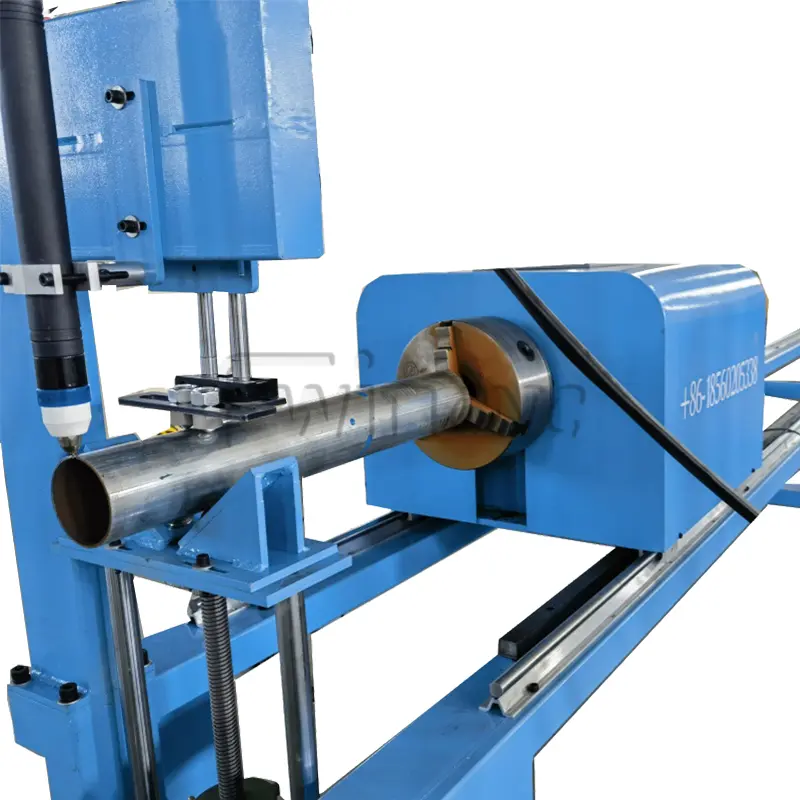

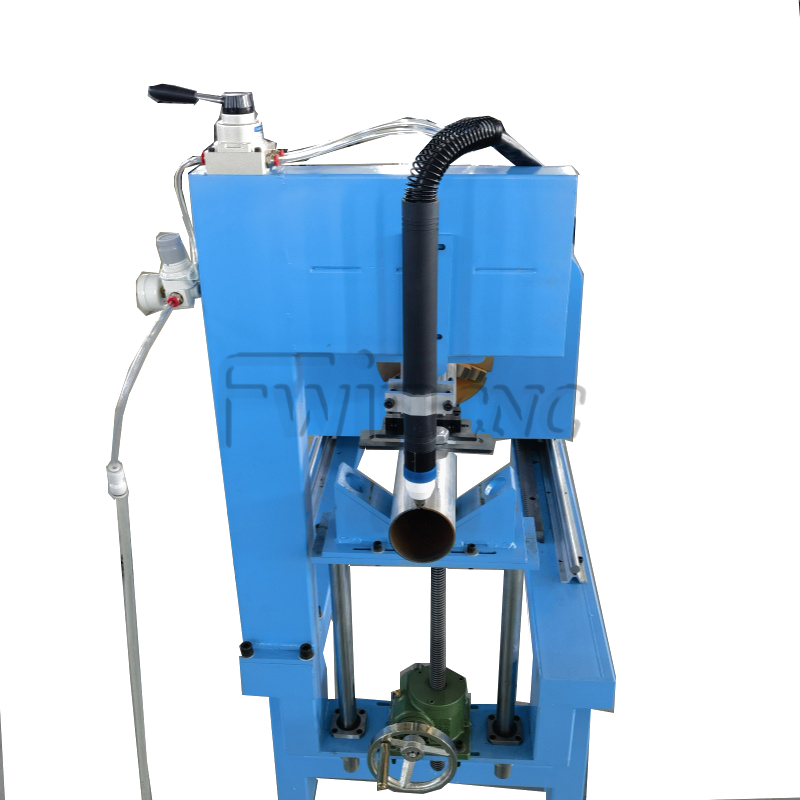

Equipped with an advanced CNC control system, this metal tube cutting machine ensures synchronized pipe rotation and torch movement. The coordinated multi-axis operation enables accurate contour cutting, saddle cuts, intersecting holes, and complex pipe joint processing.

The CNC plasma cutting system provides stable arc performance, smooth kerf edges, and reduced slag formation, minimizing post-processing work and improving production efficiency.

Key Features of the Round Pipe Cutting Machine

• Automated pipe rotation system for consistent and accurate cylindrical cutting

• Multi-axis CNC control for complex geometry and intersection profiles

• Wide pipe diameter compatibility for various industrial applications

• Stable plasma cutting source ensuring clean edges and reliable penetration

• Optimized structure design for durability and long-term operation

This CNC plasma tube cutter enhances productivity while maintaining high precision standards required in modern metal fabrication environments.

Technical Capabilities and Processing Range

The Round Pipe Cutting Machine supports diverse processing requirements, including orthogonal cuts, bevel cutting, hole opening, and intersecting pipe structures. Its rigid frame construction ensures cutting stability even during continuous operation.

Designed for industrial workshops and steel processing plants, this metal pipe cutting machine offers reliable performance for both batch production and customized fabrication tasks.

PLASMA TUBE CUTTER Applications

Applications in Metal Fabrication

The CNC pipe cutting system is suitable for:

• Structural steel pipe processing

• Stair handrail and railing fabrication

• Construction and infrastructure projects

• Mechanical equipment manufacturing

• Architectural metal components

With precise CNC automation and efficient plasma technology, the Round Pipe Cutting Machine improves workflow efficiency, reduces manual intervention, and ensures repeatable cutting accuracy.

Businesses seeking a durable and high-performance CNC pipe cutter will benefit from enhanced production capacity, consistent cut quality, and lower operating costs. This industrial metal tube cutting machine is engineered to deliver dependable results in demanding fabrication environments.

Gantry cnc Plasma cutter Details

Stable Frame

Plasma Torch

Common templates

package and delivery for Gantry cnc plasma cutter

The Round Pipe Cutting Machine is securely packed to ensure safe transportation. Main components are wrapped with protective film and reinforced with wooden crates or steel frames to prevent damage during shipping. Electrical parts are carefully sealed against moisture and dust.

Delivery time depends on configuration and production schedule. The machine can be shipped by sea, land, or according to customer logistics requirements. Installation guidance and technical support are provided to ensure smooth commissioning after arrival.

We also have Gantry CNC plasma cutting machine with rotary device to cut metal tubes for option.

International Shipping Around the World

All of our cutting machines can be sent to all parts of the world by sea, air, international expFEDEX, UPS, etc. You are welcome to feedback your needs and we can provide you with the most timely and accurate freight quotation, as well as the most timely and reliable service