Engineered for stability and durability, this industrial stud welding system reduces downtime thanks to its robust construction and straightforward maintenance. Its versatility across stud sizes and base metals helps shops consolidate equipment needs and simplifies operator training. These benefits translate into lower operating costs and higher throughput for manufacturers and fabricators seeking dependable stud welding solutions.

High-Efficiency Plasma Stud Welding Machine for Industrial Applications

The industrial Plasma Stud Welding Machine integrates a robust power source, precision welding gun, and automatic stud feeding/positioning mechanism to deliver rapid stud attachment with minimal operator intervention. Stud welding is a fast joining process that creates a metallurgical bond between a stud and a base metal using an electric arc and controlled force, eliminating the need for holes or filler materials. This method produces durable, high-strength connections and is widely accepted in structural fabrication due to its efficiency and reliability.

Suitable for both automation and manual operation, the Plasma Stud Welding Machine supports diverse production needs and adapts easily to workshop or assembly lines where strong welded connections are critical.

CNC and Manual Torch Compatible Plasma Source

| Project Name | Unit | Model | ||

| PSN-1600A | PSN-2500A | PSN-3150A | ||

| Input voltage | V/Hz | 3~380V 50/60 | ||

| Rated input capacity | KVA | 73.5 | 107 | 145 |

| Rated input power | KW | 69 | 94 | 126 |

| Rated input current | A | 112 | 165 | 225 |

| Rated output voltage | V | 32 | ||

| Efficiency | —— | 74% | 85% | 89% |

| Power factor | —— | 0.95 | 0.89 | 0.95 |

| Welding Current Regulation Range | A | 160~1600 | 250~2500 | 315~3150 |

| Welding time adjustment range | S | 0.01~9.99 | ||

| Applicable screw diameter | mm | φ6~φ19 | φ6~φ25 | φ6~φ30 |

| Applicable screw diameter | mm | ≤400 | ||

| Welding productivity | n/min | 16~25 | ||

| Power Cooling | —— | Air Cooling | ||

| Insulation Level | —— | F | ||

| Case protection level | —— | IP21S | ||

| Dimensions (length*width*height) | mm | 685*395*762 | 900X400X880 | |

| Net Weight | kg | 65 | 96 | 98 |

PRODUCT DESCRIPTIONS

1. Stable Plasma Arc Welding System

Powered by a reliable plasma arc source, the machine generates a consistent weld current that ensures clean fusion between studs and base materials, reducing defects and rework.

2. Versatile Stud Compatibility

Designed for a wide range of stud sizes and types, this industrial stud welder can handle common fastener diameters used in heavy fabrication tasks, improving workflow flexibility.

3. Automatic Positioning and Feed Mechanism

The integrated feed and positioning system speeds up welding cycles and reduces manual setup time, enabling faster throughput in repetitive production environments.

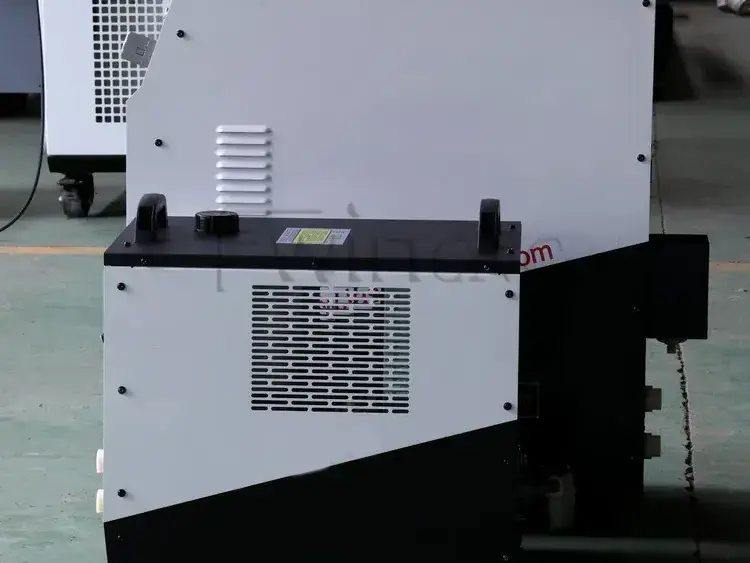

4. Rugged Industrial Construction

Built with durable components and robust housing, the stud welding machine withstands demanding workshop conditions and maintains performance over long operating hours.

5. User-Friendly Control Interface

Intuitive controls allow operators to adjust welding parameters with ease, fine-tuning power levels and weld timing for optimal results based on material type and thickness.

Application industries for Head Plasma Cutting Bevel Machine

• Structural steel fabrication and assembly

• Automotive manufacturing and bodywork joining

• Construction site fastening and reinforcement

• Heavy machinery and equipment assembly

• Mechanical workshop fabrication and maintenance

Enhanced Cutting Performance and Productivity

The Plasma Stud Welding Machine dramatically increases production efficiency by reducing cycle times compared to traditional fastening methods. Stud welding can join studs in a single, rapid operation, lowering labor demand and enabling consistent weld quality across every connection. By minimizing heat-affected zones and avoiding secondary machining, this machine delivers strong welds with excellent repeatability for high-volume fabrication environments.

Reliable Industrial Performance and Cost Savings

Related Products for metal fiber laser cutter

ALLWIN CATALOGUE

GET FREE QUOTE NOW!